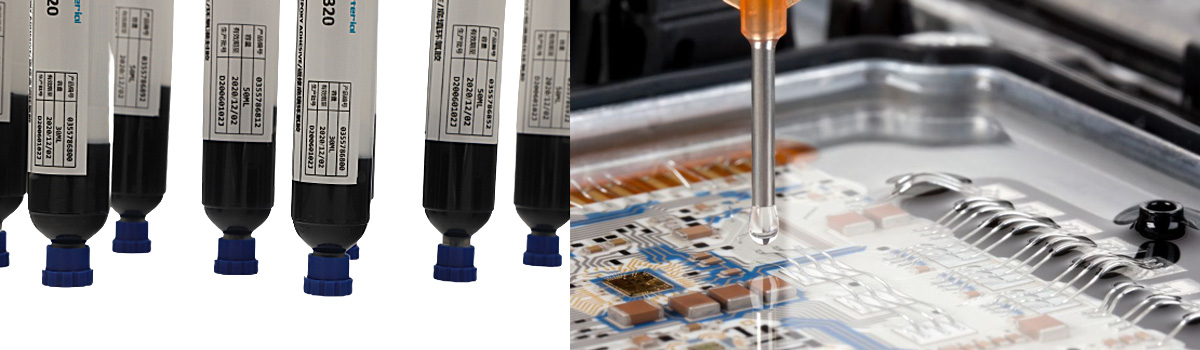

UV glue for glass is an adhesive that uses ultraviolet light to cure and bond glass surfaces together. Unlike traditional glass bonding methods that require high heat or pressure to create a bond, UV glue bonding is a more efficient and cost-effective process.

UV glue for glass works by using photoinitiators that react with ultraviolet light, triggering a polymerization process that bonds the two glass surfaces together. This bonding method offers numerous benefits over traditional methods, including higher bond strength, faster curing time, and improved optical clarity.

Types of UV Glue for Glass

There are several types of UV glue for glass, each with unique characteristics and benefits. The four most common types of UV glue for glass are acrylic-based, epoxy-based, silicone-based, and polyurethane-based.

- Acrylic-based UV glue is a popular option for glass bonding due to its fast curing time and excellent optical clarity. This type of UV glue is ideal for applications that require a strong bond and a clear finish, such as bonding glass screens for electronics or creating glass displays.

- Epoxy-based UV glue is another common type of UV glue for glass. It has excellent bond strength and is highly resistant to temperature changes and chemicals. The automotive industry commonly uses epoxy-based UV glue to bond windshields and mirrors.

- Silicone-based UV glue is a highly flexible and durable adhesive that withstands extreme temperatures and weathering. The construction industry often uses it to bond glass facades and shower enclosures.

- Polyurethane-based UV glue is a versatile adhesive that binds various materials, including glass, metal, and plastic. The medical industry commonly uses UV glue to bond surgical instruments and medical devices.

Benefits of UV Glue for Glass Bonding

UV glue for glass bonding offers numerous benefits over traditional bonding methods. Some of these benefits include:

Fast curing time: UV glue for glass bonding can cure in seconds, making it a highly efficient bonding method.

High bond strength: UV glue for glass bonding provides a solid and durable bond that can withstand various environmental factors.

High optical clarity: UV glue for glass bonding offers a clear and transparent finish that does not obstruct the view of the bonded surfaces.

Resistance to UV light and weathering: UV glue for glass bonding is highly resistant to UV light and weathering, making it an ideal bonding method for outdoor applications.

Wide range of applications: UV glue for glass bonding has many applications in various industries, including automotive, electronics, construction, and medical.

Cost-effectiveness: UV glue for glass bonding is more cost-effective than traditional methods requiring high heat or pressure.

Applications of UV Glue for Glass Bonding

Various industries use UV glue for glass bonding due to its versatility and unique properties. Some of the industries that use UV glue for glass bonding include:

Automotive industry: The automotive sector commonly uses UV glue for glass bonding to bond windshields, headlights, and mirrors. UV glue’s fast curing time and high bond strength make it an ideal bonding method for automotive applications.

Electronics industry: The electronics industry benefits from using UV glue for glass bonding in applications like LCD screens and touch panels. UV glue offers high optical clarity, fast curing times, and resistance to environmental factors, making it ideal for electronic devices that require sleek and seamless designs.

Construction industry: The construction industry commonly uses UV glue for glass bonding to bond glass facades and shower enclosures. The resistance to weathering and UV light makes it

ideal for outdoor applications.

Medical industry: In the medical industry, many medical devices and surgical instruments use UV glue for glass bonding to achieve strong bonds. The versatility and cost-effectiveness of UV glue make it an ideal bonding method for medical applications.

Tips for Using UV Glue for Glass Bonding

UV glue for glass bonding requires proper surface preparation, application techniques, and curing and storage conditions. Here are some tips for using UV glue for glass bonding:

Surface preparation and cleaning: To bond the glass surfaces properly, one should clean them thoroughly with alcohol or mild detergent to remove any dirt or contaminants. The characters should be completely dry before applying UV glue.

Proper application techniques: UV glue should be applied sparingly and evenly to bond the glass surfaces. Excess adhesive can lead to poor bond quality, while insufficient glue can weaken bonding.

Choosing the correct type of UV glue: The type of UV glue selected for a particular application will depend on the application’s specific requirements. For example, an epoxy-based UV glue may be the best option if high bond strength is required.

Proper curing and storage conditions: UV glue should be cured under appropriate conditions to ensure a solid and durable bond. The recommended curing time and conditions will vary depending on the type of UV glue used. It is also essential to store UV glue in a cool and dry place to prevent degradation.

UV glue for glass bonding is a highly efficient and cost-effective method that offers numerous benefits over traditional bonding methods. The different types of UV glue for glass provide unique characteristics and benefits, making it ideal for various automotive, electronics, construction, and medical applications.

Proper surface preparation, application techniques, and curing and storage conditions are crucial for successful UV glue bonding. Following the tips above, you can ensure a solid, durable bond between glass surfaces.

Consider using UV glue for glass bonding in your industry or application to exploit its unique properties and benefits. Whether you need to bond windshields, LCD screens, or surgical instruments, UV glue for glass bonding is a reliable and cost-effective bonding method.