UV Curing Adhesive

A Comprehensive Handbook On UV Curing Adhesive: Characteristics, Uses, and Optimal Techniques

Best UV Curing Adhesive Manufacturer and Supplier in China

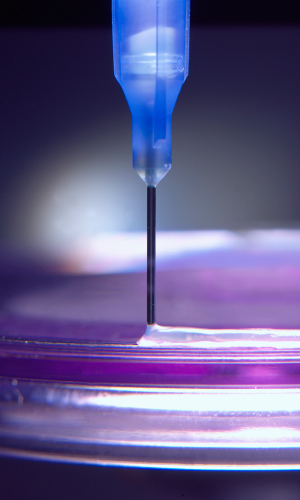

Deepmaterial has been supplying the UV curing adhesives for electronics, transportation, medical and many other industries with high-grade materials from our factory in the China. Our UV Light curing adhesives are widely used across a broad range of market sectors and include the manufacture of disposable medical devices such as syringe needle bonding, plastic tube & bag sets. Our medical UV adhesives are approved to USP Class VI or ISO 10993 biocompatibility standards. Other applications include splicing and bonding of fibre optic filaments, lens bonding, fabricating acrylic or glass display cases, Retail point of sale products such as shelving units, plynths, awards, trophies, cabinets, signs and decorative artwork.

What is UV curing adhesive?

UV curing adhesive is a type of adhesive that is cured or hardened through ultraviolet light. This process, also known as photo-polymerization, involves using a UV light source to activate and cure the adhesive.

UV curing adhesives offer several benefits over traditional glues. They can bond with a wide range of substrates, including plastics, metals, and ceramics, with a solid and durable bond. They also cure quickly, which makes them ideal for high-speed production lines. UV curing adhesives do not contain solvents or other volatile organic compounds, making them environmentally friendly and safe.

The electronics, medical, and automotive industries commonly use UV curing adhesive because they require its fast curing time and strong bond. Manufacturers of glass and plastic products and the printing industry can also utilize UV curing adhesive.

How UV Curing Adhesive Works

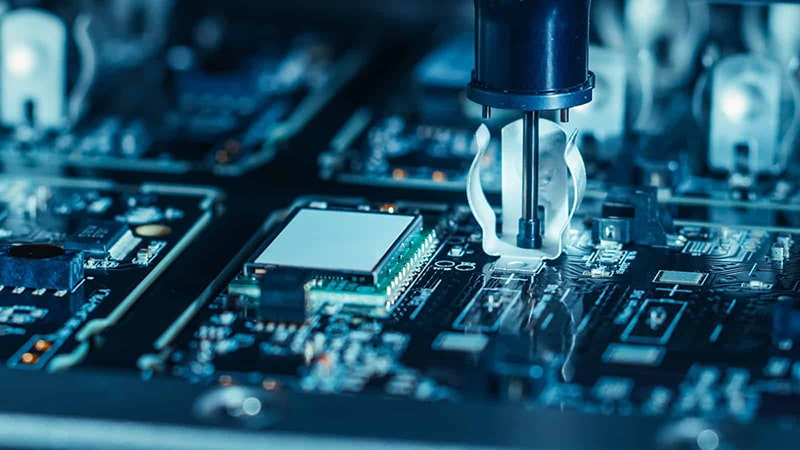

UV curing adhesives are becoming increasingly popular in the industrial world due to their quick and efficient bonding capabilities. These adhesives use ultraviolet (UV) light to initiate a chemical reaction that causes the adhesive to cure or harden. Here, we will explore how UV curing adhesive works and why it is a popular choice in manufacturing.

The first step in using a UV curing adhesive is applying the glue to the materials you want to bond. Once the sealant is applied, the materials are pressed together and exposed to UV light. This UV light triggers the photoinitiators in the adhesive, which then starts a chemical reaction known as polymerization. This reaction causes the adhesive to cure or harden, forming a solid bond between the two materials.

UV curing adhesives work because of the unique properties of the photoinitiators. Specific wavelengths of UV light activate these initiators and cause the glue to polymerize rapidly. UV curing adhesive hardens quickly, which allows for fast production times and increased efficiency in manufacturing.

One of the benefits of UV curing adhesives is that they do not require any solvents or other chemicals to work, which means they are environmentally friendly and do not produce harmful fumes or waste. UV curing adhesives can also be used on various materials, including glass, metal, and plastic, making them a versatile choice for industrial applications.

Advantages of UV Curing Adhesive

UV curing adhesives have become increasingly popular in recent years due to their numerous advantages over traditional adhesive technologies. Ultraviolet light cures these adhesives by initiating a polymerization reaction, which forms strong bonds between substrates. This blog post will discuss the advantages of UV curing adhesives.

- Fast Cure Time: One of the main advantages of UV curing adhesives is their fast cure time. These adhesives can be cured in seconds, allowing for shorter production times and increased efficiency. The fast-curing property of UV curing adhesive is especially beneficial in industries where speed is critical, such as electronics, medical devices, and automotive manufacturing.

- Strong Bonds: UV curing adhesives form solid and durable bonds between substrates, making them ideal for various applications. They can quickly bond dissimilar materials, such as plastic to metal or glass to plastic. Additionally, these adhesives provide excellent adhesion to difficult-to-bond materials, such as polypropylene and polyethylene.

- Reduced VOCs: Unlike traditional solvent-based adhesives, UV curing adhesives do not emit volatile organic compounds (VOCs) during the curing process. UV curing adhesives make them more environmentally friendly and safer for workers to handle.

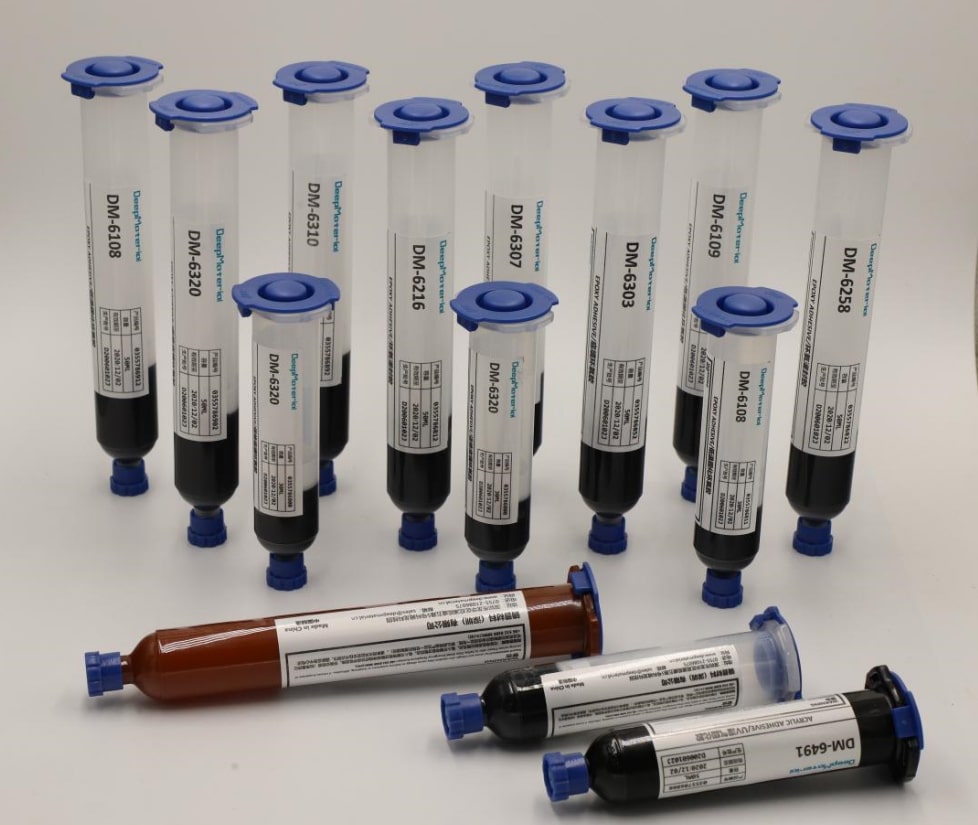

- Easy to Use: UV curing adhesives are easy to use and require minimal preparation. UV curing adhesives do not need special storage conditions or mixing, and manufacturers can apply them using various dispensing methods, such as syringes, spray guns, and automated dispensing equipment.

- Versatility: Manufacturers can use UV curing adhesives in multiple applications, such as medical devices, automotive components, electronics, and optics, due to their versatility. They can also bond flexible substrates, such as textiles and films.

Types of UV Curing Adhesive

Several UV curing adhesives are available, each with unique properties and applications. The selection of suitable adhesives depends on the specific requirements of the application. Manufacturers should consider the substrate materials, environmental conditions, and the required bond strength when selecting the appropriate adhesive. With the proper selection, UV curing adhesives can provide fast and robust bonds resistant to harsh environments, making them a valuable tool in various industries. Here, we will discuss the different types of UV curing adhesives available and their unique properties.

Acrylated Epoxies: Acrylated epoxies are UV curing adhesives often used in electronics and medical device applications. They offer high bond strength and excellent chemical resistance, ideal for harsh environments. Acrylated epoxies are also known for their excellent adhesion to various substrates, including metals, plastics, and ceramics.

Acrylics: Manufacturers can use acrylic UV curing adhesives outdoors because of their excellent UV resistance. They also provide high bond strength and excellent adhesion to various substrates, including plastics, metals, and glass. Manufacturers often use acrylics in the automotive industry to bond exterior components.

Silicones: Silicone UV curing adhesives are known for their excellent flexibility and high-temperature resistance. Manufacturers often use them in aerospace to bond components exposed to extreme temperatures. Additionally, Silicones provide excellent adhesion to plastics and metals.

Cyanoacrylates: Cyanoacrylates, known as instant adhesives, offer speedy cure times and high bond strength. Manufacturers often use them in medical device applications, such as bonding catheters and tubing. However, manufacturers cannot use them in applications exposed to UV light.

Epoxy Acrylates: Epoxy acrylates are hybrid UV curing adhesives that combine the properties of epoxies and acrylates. Due to their high bond strength and excellent chemical resistance, manufacturers often use them in demanding applications, such as aerospace and defense.

Applications of UV Curing Adhesive

UV curing adhesives are an adhesive that cures when exposed to ultraviolet light. This technology has gained popularity recently due to its quick curing time, high bonding strength, and environmental friendliness. Manufacturers can use UV curing adhesives in a variety of applications. Here, we will explore some of the most common applications of UV curing adhesives.

Electronics Industry

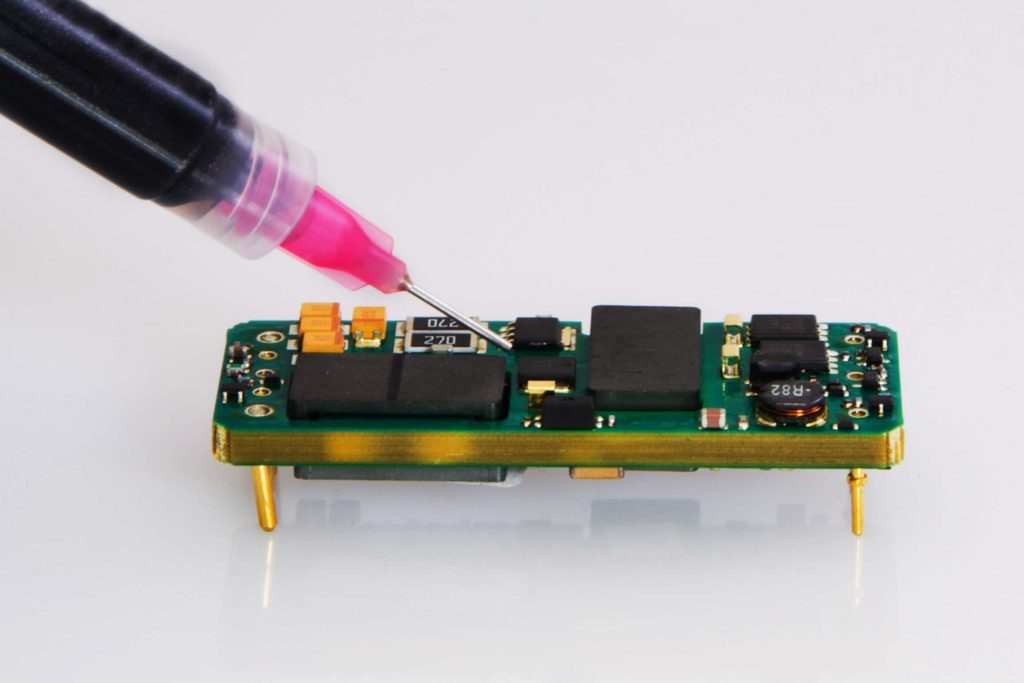

One of the most common applications of UV curing adhesives is in the electronics industry. UV curing adhesives can bond materials such as glass, metal, and plastic, making them ideal for producing electronic devices. They are often used to bond circuit boards, LCDs, and touch screens.

Medical Devices

UV curing adhesives are also widely used in the production of medical devices. They bond materials such as plastic, glass, and metal in medical devices such as catheters, IV sets, and syringes. UV curing adhesives are preferred in the medical industry because they are non-toxic and do not emit harmful fumes.

Automotive Industry

Manufacturers also use UV curing adhesives in the automotive industry. They bond various materials, such as glass, plastic, and metal. UV curing adhesives are preferred over traditional adhesives because they have a faster curing time, which helps to speed up the production process.

Aerospace Industry

Manufacturers commonly use UV curing adhesives in the aerospace industry. They bond materials such as composites, metal, and plastic. UV curing adhesives are preferred in the aerospace industry because they are lightweight and have a high bonding strength.

Printing Industry

Manufacturers also use UV curing adhesives in the printing industry. They are used to bond paper, plastic, and other materials to produce labels, packaging, and other printed materials. UV curing adhesives are preferred in the printing industry because they have a fast curing time, which allows for faster production speeds.

Industries that use UV Curing Adhesive

UV curing adhesive is a type of adhesive that is cured or hardened by exposure to ultraviolet (UV) light. This technology has revolutionized many industries by offering fast and efficient bonding solutions. Here are some of the industries that use UV curing adhesives:

Electronics Industry

The electronics industry relies heavily on UV curing adhesive, and these adhesive bond components are on circuit boards, LCDs, touchscreens, and other electronic devices. The fast curing time of UV adhesive makes it ideal for high-volume production environments.

Medical Industry

The medical industry uses UV curing adhesive for bonding medical devices and equipment, and this adhesive is handy for bonding catheters, needles, and other medical instruments. UV adhesive’s fast curing time helps reduce production time and improve efficiency in medical manufacturing.

Automotive Industry

Manufacturers use UV curing adhesive in the automotive industry to bond plastic and metal components. This adhesive is handy for connecting interior and exterior trim, instrument panels, and headlights. UV curing adhesive provides strong, durable bonds that withstand harsh environmental conditions.

Aerospace Industry

The aerospace industry uses UV curing adhesive for bonding and sealing components on aircraft. This adhesive is handy for bonding composite materials and other lightweight materials, and UV curing adhesive provides a strong and durable bond resistant to high temperatures and harsh environmental conditions.

Packaging Industry

The packaging industry uses UV curing adhesive for bonding and sealing cartons, bags, and other packaging materials. This adhesive provides a strong, durable bond resistant to moisture, heat, and chemicals. UV curing adhesive is beneficial for high-speed production environments.

How to Apply UV Curing Adhesive

However, to achieve the best results, it is essential to apply the adhesive correctly. Here are some tips on how to use UV curing glue:

- Prepare the Surface: The first step is to prepare the surface you will bond with. Ensure it is clean, dry, and free from contaminants that could interfere with the bonding process. If necessary, use a solvent to clean the surface thoroughly.

- Apply the Adhesive: Apply the UV curing adhesive to one of the surfaces you will be bonding. The sealant applied should be sufficient to create a thin and even layer. Manufacturers must ensure that they spread the glue evenly since any lumps or bumps could impact the strength of the bond.

- Position the Second Surface: After applying the adhesive, carefully position the second surface to be bonded. Manufacturers must ensure they align the two characters correctly since they cannot reposition the glue once it cures.

- Cure the Adhesive: The final step is to fix the adhesive using UV light. The required curing time depends on the adhesive type used and the adhesive layer’s thickness. Typically, curing times range from a few seconds to a few minutes. Manufacturers must follow the instructions for curing times to ensure that the adhesive cures entirely and that the bond is strong.

Factors to Consider When Choosing UV Curing Adhesive

Choosing the proper UV curing adhesive for your project requires careful consideration of material compatibility, bond strength, cure time, environmental conditions, and application method. Considering these factors, you can select an adhesive that will provide a robust and reliable bond for your application. Here are some factors to consider when choosing UV curing adhesive for your project:

Material compatibility: The first thing you must consider when choosing a UV curing adhesive is the material you will be bonding. Selecting a sealant compatible with your working materials is essential; different materials require different adhesives explicitly designed for them.

- Check the adhesive’s datasheet or contact the manufacturer to ensure it will work with your specific materials.

- Another essential factor to consider is the strength of the bond you need. UV curing adhesives are available in different strengths, from low to high, so choosing one that will provide the necessary power for your application is essential.

- UV curing adhesives cure quickly under UV light, but different bonds have different cure times. Some cure in seconds, while others may take several minutes. Consider how much time you have for the adhesive to cure and choose a bond that will fix within that time frame.

Environmental conditions: When choosing an adhesive, it is essential to consider the environmental conditions to which it will be exposed.

- The person selecting the adhesive should consider whether the glue might encounter heat, moisture, or chemicals and choose a bond designed to withstand those conditions.

- Finally, consider the application method. Consider whether applying the UV curing adhesive requires special dispensing equipment, as some may need it, while others can be applied using a brush or syringe. Choose a bond that can be easily applied using your preferred method.

Proper Storage and Handling of UV Curing Adhesive

Like any adhesive, improper storage and handling of UV curing adhesive can lead to performance issues and potential safety hazards. This blog post will discuss the proper storage and handling of UV curing adhesive to ensure optimal performance and safety.

Proper Storage

- Store UV curing adhesive in a cool, dry place away from direct sunlight and heat sources. Exposure to heat can cause the glue to cure prematurely and reduce its shelf life.

- Keep the adhesive container tightly sealed when not in use to prevent moisture and air from entering the container. Exposure to air and humidity can also cause premature curing and degrade the adhesive’s performance.

- Store the adhesive container upright to prevent settling and separation of components.

Proper Handling

- When handling UV curing adhesive, always wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Mix the adhesive thoroughly before use to ensure consistent performance. Follow the manufacturer’s instructions for mixing and dispensing the adhesive.

- Apply the adhesive evenly and avoid over-application to prevent the excess glue from curing and interfering with the bond.

- Use UV protective barriers, such as UV-blocking curtains or shields, to prevent accidental exposure to UV radiation during curing.

- Dispose of unused adhesive according to the manufacturer’s instructions and local regulations.

In addition to proper storage and handling, using the appropriate UV curing equipment for the adhesive is essential. UV curing adhesives require a specific wavelength and intensity of UV radiation to cure appropriately. Using the right UV source or insufficient curing time can result in a solid or incomplete bond.

Safety Precautions When Working with UV Curing Adhesive

UV curing adhesive is famous for bonding in various industries due to its fast curing time and strong bonding properties. However, UV curing adhesive can be hazardous if not handled with care like any other adhesive. Here are some essential safety precautions to follow when working with UV curing adhesive:

Wear appropriate personal protective equipment (PPE)

- Safety glasses or goggles: UV light can harm the eyes, so wear appropriate safety glasses or goggles with UV protection.

- Gloves: Wear chemical-resistant gloves to protect the hands from contact with the adhesive.

- Protective clothing: Wear protective clothing to cover the skin and prevent contact with the glue.

Ensure proper ventilation

- Work in a well-ventilated area to prevent the accumulation of vapors that can harm health.

- Use exhaust fans or wear a respirator if working in a confined space or with large quantities of adhesive.

Store and handle the adhesive properly

- Store the adhesive in a cool, dry, well-ventilated area away from heat sources, flames, or direct sunlight.

- Keep the adhesive container tightly closed when not in use.

- Handle the adhesive with care, and avoid dropping or puncturing the container.

Follow the manufacturer’s guidelines

- Read and follow the manufacturer’s instructions for use and safety precautions.

- Use the adhesive only for its intended purpose and recommended applications.

- Do not modify or mix the bond with other materials without the manufacturer’s approval.

Dispose of the adhesive and waste properly

- Dispose of the adhesive and waste according to local regulations and guidelines.

- Do not pour the glue down the drain or dispose of it in the regular trash.

By following these safety precautions, one can safely work with UV curing adhesive and avoid potential hazards. It is also important to receive training and certification before handling and working with UV curing adhesive, especially in industrial settings.

Troubleshooting Common Issues with UV Curing Adhesive

UV curing adhesive is famous for bonding in various industries due to its fast curing time and strong bonding properties. However, like any other adhesive, UV curing adhesive can also face some common issues that can affect the quality of the bond. Here are some troubleshooting tips for common problems with UV curing adhesive:

Issue: Incomplete curing of the adhesive

- Cause: Insufficient UV light exposure or incorrect intensity setting

- Solution: Increase the UV light exposure time or adjust the intensity setting to the recommended level

Issue: Poor bond strength

- Cause: Contaminated surface or improper surface preparation

- Solution: Clean the surface thoroughly before applying the adhesive and follow the recommended surface preparation guidelines

Issue: Adhesive not adhering to a specific material

- Cause: Material not compatible with UV light or the adhesive

- Solution: Use a different adhesive that is compatible with the material or look for a UV-compatible version of the material

Issue: Adhesive discoloration or yellowing

- Cause: Overexposure to UV light or exposure to high temperatures

- Solution: Reduce the exposure time or temperature, or use a UV stabilizer to prevent discoloration

Issue: Adhesive peeling off after curing

- Cause: Inadequate pressure or incorrect curing conditions

- Solution: Increase the pressure applied during bonding or adjust the curing conditions to the recommended settings

Issue: Adhesive dripping or running

- Cause: Adhesive applied in excessive quantities or improper application technique

- Solution: Apply the adhesive in thin and even layers, and follow the recommended application guidelines

Please note that these troubleshooting tips provide general guidelines only, and an issue’s specific cause and solution may vary depending on the application and materials involved. Experts always recommend referring to the manufacturer’s guidelines and seeking expert advice if a problem persists.

Differences Between UV Curing Adhesive and Other Adhesives

Regarding adhesive bonding, various types of adhesives are available in the market, each with its unique properties and features. Two common types of adhesives used in industrial and commercial applications are UV curing adhesive and other adhesives such as cyanoacrylate, epoxy, and acrylic. While they may seem similar in function, the two have some significant differences.

UV curing adhesive is an adhesive that hardens when exposed to ultraviolet (UV) light. It is a solvent-free adhesive that contains photoinitiators that activate and set the adhesive when exposed to UV light. On the other hand, other adhesives, such as cyanoacrylate, epoxy, and acrylic, require heat or chemical reaction to harden.

One of the critical differences between UV curing adhesive and other adhesives is the curing time. UV curing adhesive cures almost instantly when exposed to UV light, making it a popular choice in industries that require fast bonding, such as electronics and automobiles. Other adhesives, however, may take several hours or even days to cure completely.

Another advantage of UV curing adhesive is that it is solvent-free, making it eco-friendly and non-toxic. Other bonds, such as cyanoacrylate and epoxy, contain solvents that may harm the environment and human health.

UV curing adhesive also offers excellent bonding strength and durability. It can bond to various materials, including glass, metal, plastic, and ceramics. Its high bonding strength makes it suitable for applications that require strong and long-lasting bonding, such as medical devices, aerospace, and defense equipment.

While UV curing adhesive offers many advantages, it also has some limitations. UV light cannot bond materials that do not transmit it, such as certain plastics and colored glass. Other adhesives like epoxy and acrylic may be more suitable for connecting these materials.

How to Cure UV Curing Adhesive

Properly curing the adhesive is very important to ensure it achieves the desired level of strength and durability. Here we will discuss how to cure UV curing adhesive.

Here are some steps to properly cure UV curing adhesive:

- Prepare the substrate: To ensure a proper bonding process, clean and dry the substrate to remove any contaminants or debris before applying the UV curing adhesive. The surface should also be free from oils, grease, or other substances that can interfere with curing.

- Apply the adhesive: Apply the UV curing adhesive to the substrate using the recommended amount and method of application. Be sure to apply the glue evenly and avoid any excess that may cause the bond to run or drip.

- Expose to UV light: Once the adhesive is applied, expose it to UV light for the recommended time. Depending on the type of adhesive and substrate used, the intensity and wavelength of the UV light may vary.

- Monitor the curing process: As the adhesive cures, monitor the process to ensure it is curing correctly. The viscosity or absorbance of the adhesive can be measured at regular intervals to accomplish this.

- Check for completeness: After the adhesive has cured, verify that it has reached the desired level of strength and has fully healed. To ascertain the power of the bond, perform a pull test or other appropriate strength test.

Properly curing UV curing adhesive is essential to ensure that it achieves the desired level of strength and durability. By following these steps and using the recommended curing methods, you can ensure that the adhesive bonds properly and provides a long-lasting, reliable solution for your manufacturing needs.

How to Measure the Cure Rate of UV Curing Adhesive

It is essential to measure the cure rate of the adhesive to ensure that it cures appropriately and achieves the desired level of strength. In this blog post, we will discuss how to measure the cure rate of UV curing adhesive.

Here are some steps to measure the cure rate of UV curing adhesive:

- Set up the test: The first step is to prepare the test samples. Apply a small amount of the UV curing adhesive to the substrate, then expose it to UV light for the recommended time.

- Prepare the testing equipment: We can use different types of equipment to measure the cure rate of UV curing adhesive. A standard method is to use a rheometer, which measures the viscosity of the glue as it heals. Alternative equipment, such as a spectrophotometer or a UV intensity meter, can also measure the cure rate of UV curing adhesive.

- Take measurements: After setting up the testing equipment, regularly take measures at intervals to track the curing process. The frequency of measurements will depend on the adhesive type and the desired accuracy level. We typically take measurements every few seconds or minutes.

- Analyze the data: After collecting the measurements, analyze the data to determine the cure rate of the adhesive. To determine the cure rate, we can plot the viscosity or absorbance readings against time and choose the slope of the curve.

- Calculate the cure time: Based on the data collected, calculate the time it takes for the adhesive to reach a specific level of cure. We can determine the cure rate by measuring the time it takes for the viscosity to reach a certain level or for the absorbance to reach a specific percentage.

Measuring the cure rate of UV curing adhesive is an essential step in ensuring that it cures appropriately and achieves the desired level of strength. By following these steps and using the appropriate testing equipment, you can accurately measure the cure rate of the adhesive and optimize your manufacturing process.

The durability of UV Curing Adhesive

One critical factor distinguishing UV curing adhesives from other bonds is their durability. In this blog post, we will discuss UV curing adhesives’ durability and why they make them an excellent choice for many applications.

UV curing adhesives form strong bonds quickly because UV light exposure triggers a chemical reaction that cures the glue and causes it to harden. Depending on the adhesive type and the UV light’s intensity, this curing process can take a few seconds.

One of the benefits of this fast curing time is that it allows for high throughput and increased productivity in manufacturing processes. However, the real advantage of UV curing adhesives lies in their durability. Once cured, these adhesives form a strong, permanent bond that withstands various environmental conditions.

UV curing adhesives are highly resistant to moisture, chemicals, and temperature extremes. The ability of UV curing adhesives to form strong bonds quickly makes them ideal for applications in industries such as automotive, aerospace, and electronics manufacturing, which often require exposure to harsh environments. They are also commonly used in medical device manufacturing, where sterility and resistance to harsh chemicals are critical.

Another advantage of UV curing adhesives is their ability to bond with various substrates. They can click plastics, metals, glass, and ceramics, making them versatile for many applications. UV curing adhesives are non-toxic and do not emit harmful fumes, making them a safer alternative to traditional solvent-based adhesives.

Environmental Impact of UV Curing Adhesive

UV curing is a popular alternative to traditional adhesive due to its fast time and low energy consumption. However, like any product, UV curing adhesive has its environmental impact, which is worth exploring.

Here are some potential environmental impacts of UV curing adhesive:

- Energy Consumption: While UV curing adhesive requires less energy to fix than traditional glue, it still requires energy to power the UV lamps. This energy consumption contributes to greenhouse gas emissions and climate change.

- Chemical Composition: The chemical composition of UV curing adhesive can also impact the environment. Some UV curing adhesives contain hazardous chemicals that can harm the environment if improperly disposed of. It is vital to use eco-friendly UV curing adhesive with minimal environmental impact.

- Waste Generation: UV curing adhesive generates waste during manufacturing like any adhesive. This waste includes empty containers, excess glue, and contaminated materials. Proper disposal and recycling of this waste are essential to reduce the environmental impact.

- Transportation: Transportation of UV curing adhesive from the manufacturing plant to the end-user can also contribute to environmental impact. The applications that benefit from the ability of UV curing adhesives to form strong bonds quickly include vehicle emissions control and packaging material manufacturing.

- End-of-Life Disposal: The end-of-life disposal of UV curing adhesive products can also impact the environment. If not properly disposed of, UV curing adhesive can contaminate soil and water systems, harming wildlife and ecosystems.

It is important to note that there are eco-friendly options for UV curing adhesive that can minimize its environmental impact. Some manufacturers offer UV curing adhesive made from renewable raw materials, which can help reduce greenhouse gas emissions and waste generation.

Future Developments in UV Curing Adhesive

UV curing adhesive has become increasingly popular in manufacturing due to its fast curing time, low energy consumption, and high bond strength. As technology continues to evolve, there are exciting future developments in UV curing adhesives that are worth exploring.

Here are some potential future developments in UV curing adhesive:

- Increased Versatility: One of the most significant future developments in UV curing adhesive is its increased versatility. Manufacturers are working on creating UV curing adhesive that can bond a broader range of materials, including those that were previously difficult to connect.

- Improved Performance: As technology advances, so performs UV curing adhesive. Manufacturers are developing adhesives with more muscular bond strength, excellent temperature resistance, and enhanced durability.

- Environmentally Friendly: With an increased focus on sustainability, there is a growing demand for environmentally friendly products. Future developments in UV curing adhesive may include more eco-friendly products, such as those that use renewable raw materials.

- New Applications: As UV curing adhesive becomes more versatile and higher-performing, new applications will likely emerge. For example, the medical industry could use UV curing adhesive to bond surgical instruments and medical devices.

- Integration with Other Technologies: UV curing adhesive could be integrated with other technologies to create even more advanced products. For example, manufacturers could combine UV curing adhesive with 3D printing to create 3D-printed objects that bond together using glue.

- Innovative UV Curing Adhesive: In the future, UV curing glue may become “smart.” Manufacturers could design UV curing adhesive to alter its properties in response to different stimuli, such as temperature or light. The ability to change its properties in response to other stimuli could have applications for UV curing adhesive in various industries, from aerospace to electronics.

- Improved Efficiency: Future developments in UV curing adhesive may focus on improving efficiency. For example, manufacturers may work on developing adhesive that cures even faster, reducing production times and costs.

How UV Curing Adhesives Revolutionized Manufacturing Processes

UV curing adhesives have revolutionized the manufacturing industry by providing a more efficient and cost-effective alternative to traditional adhesive bonding methods. These adhesives utilize ultraviolet light to initiate a curing reaction that results in a solid and durable bond between two surfaces. Here are some of the ways that UV curing adhesives have transformed manufacturing processes:

Faster curing times: Unlike traditional adhesives requiring significant drying or curing time, UV can cure in seconds. Using epoxy adhesive for the metal in manufacturing increases production speed and throughput, ultimately leading to higher output and greater profits.

Stronger bonds: UV curing adhesives can create solid and durable bonds resistant to temperature, humidity, and other environmental factors. The properties or characteristics of epoxy adhesives, such as their strength and durability, make them ideal for various industries, including automotive, aerospace, and electronics.

Improved precision: Applying UV curing adhesives precisely and accurately ensures using only the necessary glue. The precise and accurate application of UV curing adhesives helps reduce waste and improves product quality and consistency.

Reduced costs: Because UV curing adhesives cure quickly and require less adhesive to create a strong bond, they can help manufacturers save money on production costs. Additionally, they are safer for workers and the environment because they do not contain solvents or other harmful chemicals.

The Future of Bonding: UV Curing Adhesives and Their Growing Market

UV curing adhesives are a type of adhesive that uses ultraviolet (UV) light to cure and harden. They have been gaining popularity recently due to their fast curing times, low VOC emissions, and ability to bond with various substrates. The market for UV curing adhesives is expected to continue to grow in the coming years, driven by several factors.

One of the primary drivers of the UV curing adhesives market growth is the increasing demand for eco-friendly and sustainable adhesives. UV curing adhesives emit fewer volatile organic compounds (VOCs) than traditional adhesives, making them more environmentally friendly. As consumers become more environmentally conscious, the demand for eco-friendly adhesives will likely increase, driving growth in the UV curing adhesives market.

Another factor driving the growth of the UV-curing adhesives market is the increasing demand for faster and more efficient production processes. UV curing adhesives can cure in seconds, allowing shorter production times and higher throughput. Precisely and accurately applying UV curing adhesives is particularly important in electronics and medical devices, where precision and speed are essential.

The automotive and aerospace industries’ growing use of UV curing adhesives will drive the market growth of these adhesives. UV curing adhesives offer several advantages in these industries, including improved durability and resistance to heat and chemicals.

UV Curing Adhesives vs. Traditional Adhesives: Which One Should You Choose?

Choosing between UV curing and traditional adhesives depends on your application requirements and constraints. Here are some factors to consider:

Bonding strength: UV curing adhesives typically offer higher strength than traditional adhesives. However, common bonds may be better suited for specific applications with sufficient lower bonding strength.

Speed of curing: UV curing adhesives cure almost instantly when exposed to UV light, which makes them ideal for high-speed production environments. Traditional bonds can take longer to fix, which may slow down production.

Flexibility: Traditional adhesives can be more flexible than UV curing adhesives, which can be brittle in specific applications. The characteristic of traditional bonds, i.e., their flexibility, makes them more suitable for applications that require this feature.

Temperature resistance: UV curing adhesives can have excellent temperature resistance, making them ideal for applications that require high-temperature bonding. Traditional bonds may not be able to withstand high temperatures.

Cost: UV curing adhesives can be more expensive than traditional adhesives, but they can also provide cost savings in production time and efficiency.

Maximizing Efficiency and Precision with UV Curing Adhesive

UV curing adhesive is an adhesive that cures or solidifies when exposed to ultraviolet light. It has become increasingly popular in industrial applications due to its fast curing time, high bonding strength, and versatility in bonding different materials. To maximize efficiency and precision with UV curing adhesive, here are some tips:

Use the right equipment: Use equipment specifically designed for UV adhesives to ensure proper curing. To perform UV curing, one typically needs specific equipment, such as a UV curing lamp, a power supply, and a UV meter to measure the intensity of the UV light. Using the correct equipment will ensure that the adhesive cures evenly and at the correct rate.

Please choose the suitable adhesive: Many types of UV curing adhesives are available, each with unique properties. Choose a bond that is suitable for your specific application and substrate. For example, some sealants are better for bonding glass to metal, while others are better for bonding plastics.

Prepare the substrate: To ensure a strong bond, the substrate should be clean, dry, and free of contaminants such as oils or dust. Use a cleaning solution specifically designed for the substrate material to remove impurities. Some substrates may also require a primer or surface treatment before bonding.

Apply the adhesive correctly:

- Apply the glue evenly and at the right thickness for your application.

- Use a dispensing system designed for UV curing adhesives to ensure precise application.

- Avoid applying excessive sealant to prevent uneven curing or excess glue that may require removal later.

Cure the adhesive correctly: The curing process is critical to the bond strength and durability of the sealant. Ensure the substrate is appropriately aligned and placed during curing to prevent movement from compromising the bond. When performing UV curing, it is crucial to use the recommended time and intensity for the adhesive and ensure that the UV light reaches the entire bond area.

By following these tips, you can maximize the efficiency and precision of your UV curing adhesive application, resulting in strong, durable bonds that meet your industrial needs.

Resources for Learning More About UV Curing Adhesive

If you want to learn more about UV curing adhesive, a wealth of resources are available to help you understand this fascinating field of adhesive technology.

One great place to start is with industry publications and trade journals. These publications often feature articles and case studies exploring the latest advances in UV curing adhesive technology and the many applications for using these adhesives.

Another valuable resource is industry events and conferences. These events provide an opportunity to connect with other professionals in the field, attend workshops and presentations, and learn about new products and technologies.

If you’re more of a visual learner, there are also a variety of online videos and webinars that can help you understand the basics of UV curing adhesive technology. These resources can benefit those just getting started in the field and looking for an introduction to the various types of UV curing adhesives, their properties, and their applications.

Of course, a discussion of resources for learning more about UV curing adhesive would only be complete by mentioning the many manufacturers and suppliers who specialize in these products. These companies often provide detailed technical information about their products, application guides, safety data sheets, and other resources to help you select and use suitable adhesives for your specific needs.

Ultimately, the best way to learn more about UV curing adhesive is to explore the many resources available. Whether you prefer reading industry publications, attending events and conferences, or watching videos and webinars, there are plenty of opportunities to expand your knowledge and stay up-to-date on the latest advances in this exciting field.

Frequently Asked Questions About UV Curing Adhesive

UV curing adhesive is becoming increasingly popular in various industries due to its numerous benefits, including fast curing time, excellent bonding strength, and versatility. However, many people still have questions about this adhesive and its applications, and here are some of the most frequently asked questions about UV curing adhesive.

What is UV curing adhesive?

UV curing adhesive is an adhesive that cures quickly under ultraviolet (UV) light. To apply the adhesive, one would first apply it to the surface of the substrate and then use a UV light source to cure it.

What are the benefits of using UV curing adhesive?

UV curing adhesive offers several benefits, including:

- Fast curing time: UV curing adhesive cures in seconds, making it ideal for high-speed manufacturing processes.

- Excellent bonding strength: UV curing adhesive provides a strong, durable bond that can withstand harsh environments.

- Versatility: Manufacturers can use UV curing adhesive on various substrates, including plastics, metals, and glass.

- No solvent emissions: UV curing adhesive is solvent-free, which means it does not emit harmful volatile organic compounds (VOCs).

What are the applications of UV curing adhesive?

Various industries use UV curing adhesive, including:

- Electronics: UV curing adhesive bonds components in electronic devices like smartphones and laptops.

- Automotive: Manufacturers commonly use UV curing adhesive to bond various car parts, including mirrors and trim.

- Medical: Manufacturers use UV curing adhesive, such as catheters and syringes, in medical devices.

- Packaging: UV curing adhesive bonds packaging materials like cardboard and plastic.

How do I apply UV curing adhesive?

UV curing adhesive is applied similarly to other adhesives using a dispenser or applicator. The bond is then exposed to UV light to cure.

Is UV curing adhesive safe?

UV curing adhesive is safe to use when handled properly. However, following the manufacturer’s instructions and wearing appropriate personal protective equipment (PPE) when handling UV light sources is essential.