UV adhesive has become essential in many industries due to its strong bonding capabilities, versatility, and fast curing time. UV adhesive manufacturers play a crucial role in producing and distributing this material to meet the growing demand in various sectors, including automotive, electronics, and healthcare. In this blog post, we will discuss the different types of UV adhesives, their benefits, and the role of manufacturers in producing and distributing them.

What is UV Adhesive?

UV adhesive is a type of adhesive that cures when exposed to ultraviolet light. It is a unique adhesive that does not require solvents, heat, or pressure to bond materials. Instead, it relies on a photoinitiator that reacts to UV light and initiates curing. This process makes it possible to bond materials that would be impossible to connect with traditional adhesives.

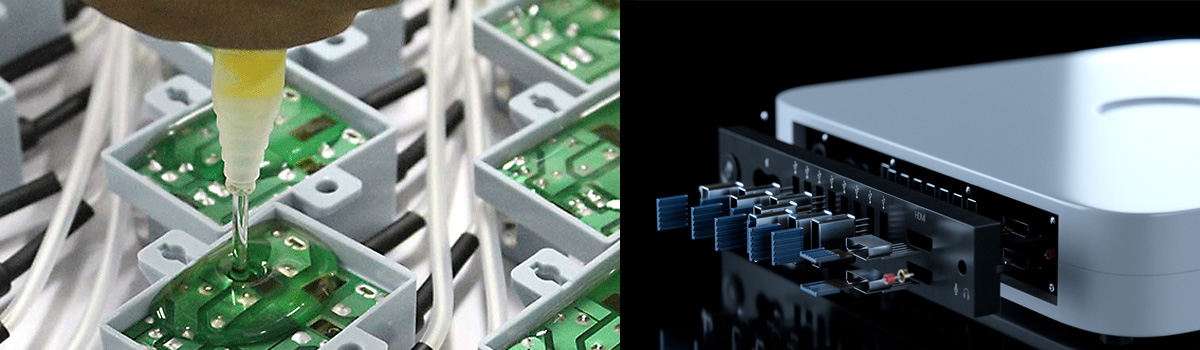

Typical UV adhesive applications include glass, plastic, and metal bonding. Medical device assembly, automotive manufacturing, and electronics assembly also use it.

Types of UV Adhesive

Different types of UV adhesives are available in the market, and each type has unique properties and is suitable for specific applications. Understanding the different kinds of UV adhesives can help you choose the right one for your project.

Acrylate-based

The electronics industry widely uses acrylate-based UV adhesives. They are fast-curing and offer strong bonding capabilities. These adhesives also resist high temperatures, chemicals, and moisture, making them ideal for harsh environments. They are also low viscosity, making them suitable for bonding small parts and components.

Epoxy-based

Epoxy-based UV adhesives are popular in the automotive and aerospace industries. They are highly durable and offer excellent bonding strength, even under extreme conditions. They also resist temperature fluctuations, vibration, and impact, making them ideal for high-stress applications.

Silicone-based

Medical device assembly and electronic manufacturing commonly use silicone-based UV adhesives. They are biocompatible and offer excellent adhesion to plastics, metals, and glass. They also have a low modulus of elasticity, which makes them suitable for bonding flexible materials.

Polyurethane-based

Many applications, including automotive, construction, and furniture manufacturing, use polyurethane-based UV adhesives. They offer high strength and flexibility, making them suitable for bonding dissimilar materials. They are also resistant to abrasion, impact, and weathering.

Others

Other types of UV adhesive include acrylic-based, cyanoacrylate-based, and polyester-based. Each class has unique properties and is suitable for specific applications.

Benefits of UV Adhesive

In addition to its unique properties, UV adhesive offers several benefits, making it a popular choice in many industries.

Faster curing time: Compared to traditional adhesives that can take hours or even days to dry, UV adhesives cure much faster. This rapid curing time reduces production times, ultimately increasing efficiency and output.

Strong bonding capabilities: UV adhesives create solid and permanent bonds that can withstand the stresses and strains of regular use. They also bond well with various materials, including metals, plastics, and glass.

Versatility: Various applications can use UV adhesives, from automotive manufacturing to medical devices. They are also suitable for harsh environments, such as high temperatures or chemical exposure.

Low VOC emissions: Unlike traditional adhesives, which can emit harmful volatile organic compounds (VOCs), UV adhesives have low emissions and are environmentally friendly.

Cost-effectiveness: Although UV adhesives can be more expensive than traditional adhesives, their faster curing time and lower waste make them a cost-effective solution in the long run.

Role of UV Adhesive Manufacturers

UV adhesive manufacturers are crucial in producing and distributing this restorative material. They are responsible for the research and development of new products and the production and quality control of existing ones.

Research and development: UV adhesive manufacturers invest heavily in research and development to create new products and improve existing ones. They test new materials and techniques and develop custom formulations for specific applications to achieve this goal.

Production and quality control: UV adhesive manufacturers are responsible for the production and quality control of a new product they develop. To ensure the product meets strict quality standards and is free from defects, they must oversee its production and thoroughly test it for any issues.

Distribution and sales: UV adhesive manufacturers work with distributors and retailers to ensure their products are widely available to customers. They also provide technical support and assistance to help customers choose the right products.

Customer support and technical assistance: UV adhesive manufacturers provide customer support and technical assistance to help customers choose the right products. As part of this support, they provide product specifications and technical data and answer questions about product performance and compatibility.

Factors to Consider When Choosing a UV Adhesive Manufacturer

Choosing the proper UV adhesive manufacturer is crucial for ensuring that your business has access to high-quality products and technical support. Here are some factors to consider when selecting a manufacturer:

Industry experience and expertise: Look for a manufacturer with experience and knowledge in your industry. They should have a deep understanding of your industry’s unique requirements and challenges and be able to provide tailored solutions to meet your needs.

Product quality and certifications: Ensure your chosen manufacturer produces high-quality products that meet industry standards and certifications. Look for certifications such as ISO 9001 and ISO 14001, which indicate a commitment to quality and environmental responsibility.

Production capacity and flexibility: Choose a manufacturer with sufficient production capacity to meet your needs and the flexibility to handle custom orders and quick turnarounds.

Customer support and technical assistance: Look for a manufacturer that provides excellent customer support and technical assistance. They should be able to answer your questions promptly and provide you with the technical data and support you need to make informed decisions.

Pricing and delivery options: Finally, consider pricing and delivery options when choosing a manufacturer. Look for a manufacturer that offers competitive pricing and flexible delivery options to meet your needs.

UV adhesive manufacturers are critical in meeting the growing demand for this important material. Understanding the types of UV adhesives, their benefits, and the role of manufacturers can help companies make informed decisions when choosing a supplier. By partnering with a reputable manufacturer, businesses can ensure they have access to high-quality products and technical support to meet their unique needs. Companies can achieve stronger bonds, faster curing times, and more efficient and cost-effective operations with the proper manufacturer.