UV-activated glue is a powerful bonding agent with many benefits, including rapid curing times, high bond strength, and versatility in bonding various materials. However, choosing the best UV-activated glue can be challenging. In this blog post, we’ll discuss the key factors to consider when selecting the best product for your specific needs and explore the different types of UV-activated glue available.

UV-activated glue is famous for bonding materials, including plastics, metals, and glass. It is a powerful adhesive activated by UV light, which causes it to cure quickly and form a strong bond.

In this blog post, we’ll explore the benefits of UV-activated glue, the key factors to consider when selecting the best product for your specific needs, and the different types of UV-activated glue available.

What is UV-activated glue?

Exposure to UV light activates UV-activated glue, a type of adhesive. Manufacturers mix acrylic, epoxy, or polyurethane resins with a photoinitiator chemical to make the adhesive. When exposed to UV light, the photoinitiator chemical triggers a reaction that quickly causes the adhesive to cure and form a strong bond.

Benefits of UV-activated glue

There are several benefits to using UV-activated glue, including the following:

Rapid curing times

UV-activated glue can cure quickly, often in just a few seconds. This property makes it an ideal choice for applications where speed is essential, such as manufacturing and production environments.

High bond strength

UV-activated glue creates a strong bond that is resistant to impact and vibration. Additionally, the adhesive’s chemical resistance makes it suitable for applications where the bond may come into contact with harsh chemicals.

Versatility in bonding various materials

UV-activated glue can bond various materials, including plastics, metals, and glass. The ability of UV-activated glue to be used in multiple applications makes it a versatile adhesive. Manufacturers, engineers, and other professionals often choose this adhesive for its flexibility and ease of use.

Key factors to consider when selecting the best UV-activated glue

When selecting the best UV-activated glue for your needs, there are several key factors to consider:

Material compatibility

Choosing a UV-activated glue compatible with the materials you are bonding with is essential. Manufacturers design some adhesives for certain materials, such as plastics or metals. Therefore, it is crucial to select the appropriate product for your application.

Curing requirements

Different UV-activated glues have additional curing requirements, and some require a specific type of UV light, while others may cure with a broader range of wavelengths. It’s essential to understand the curing requirements of your adhesive and ensure you have the appropriate equipment to fix it.

Application requirements

You should also consider the application requirements of the adhesive when choosing the best product for your needs. For example, some bonds may require a specific temperature or humidity range for optimal performance.

Environmental considerations

Environmental factors such as temperature, humidity, and exposure to chemicals can all impact the performance of UV-activated glue. Selecting an adhesive that manufacturers design to perform well in the environment in which you will use it is essential. Engineers, manufacturers, and other professionals should consider this when choosing an adhesive.

Types of UV-activated glue

There are several types of UV-activated glue available, including:

Acrylic-based

Acrylic-based UV-activated glue is a popular choice for bonding plastics and other materials. It is known for its high strength and fast curing times.

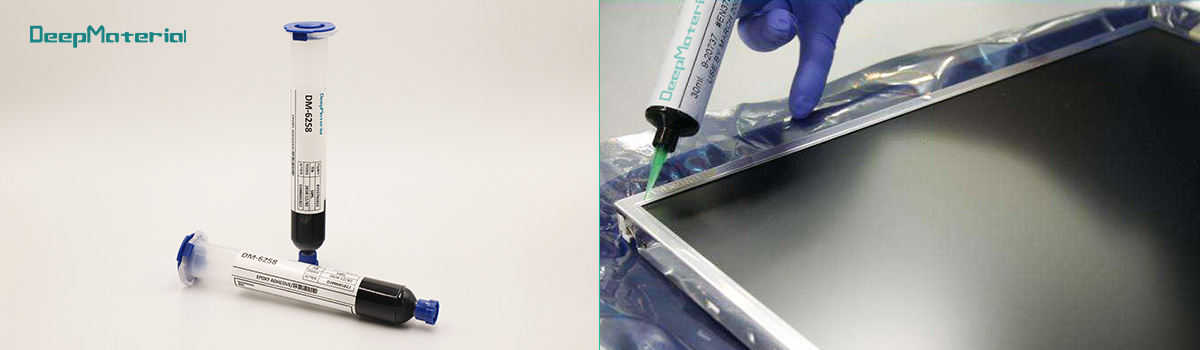

Epoxy-based

Professionals often use epoxy-based UV-activated glue when they require high strength and durability in their applications. It is a good choice for bonding metals, ceramics, and other hard materials.

Polyurethane-based

Manufacturers, engineers, and other professionals often use polyurethane-based UV-activated glue to bond various materials, including plastics, metals, and wood. Polyurethane-based UV-activated glue is because it is a versatile adhesive that can perform well in multiple applications, and it is known for its flexibility and resistance to impact.

Top considerations when choosing the best UV-activated glue

When selecting the best UV-activated glue for your needs, there are several key considerations to keep in mind:

Bonding strength and durability

The bonding strength and durability of the adhesive are essential factors to consider. It’s important to choose an adhesive that is strong enough to withstand the stresses of your application, and that will remain bonded over time.

Chemical resistance

If your application involves exposure to chemicals, it’s essential to choose an adhesive resistant to the specific chemicals you will be using.

Curing speed and efficiency

The curing speed and efficiency of the adhesive can impact the speed and efficiency of your production process. Choosing an adhesive that cures quickly and efficiently is essential to minimize production time.

Color and appearance

In some applications, the color and appearance of the adhesive may be necessary. UV-activated glue is available in a range of colors, so it’s crucial to choose a product that will blend in with your application.

Ease of use

Finally, ease of use is essential when selecting the best UV-activated glue. Some adhesives may require specialized equipment or techniques, so choosing a product that is easy to apply and use is necessary.

Applications of UV-activated glue

UV-activated glue is used in a wide range of applications, including:

Automotive industry

Due to its strength and durability, the automotive industry often uses UV-activated glue to bond plastic components and glass. Professionals choose this adhesive for its ability to provide a strong bond in this application.

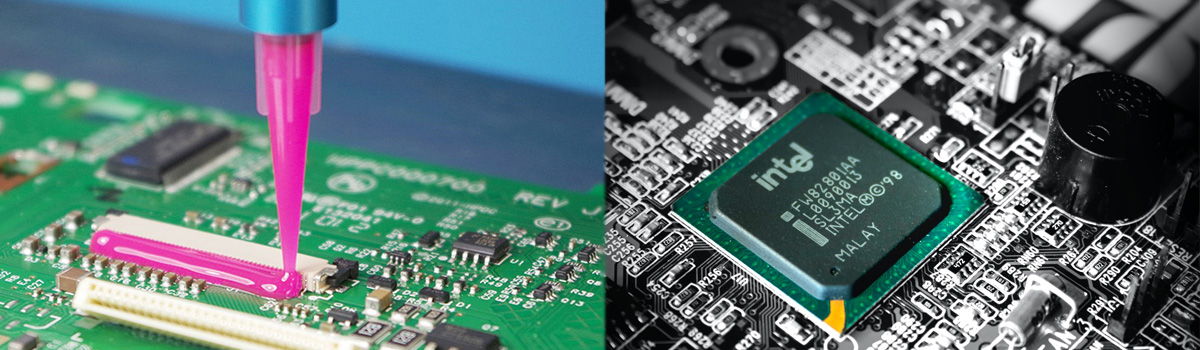

Electronics industry

Professionals in the electronics industry use UV-activated glue to bond components and PCBs. This adhesive is a popular choice due to its ability to provide a strong bond in this application. It is known for its ability to bond a wide range of materials and its rapid curing times.

Medical device industry

The medical device industry uses UV-activated glue for bonding components and sealing and coating applications. Professionals choose this adhesive for its ability to provide a strong bond and protection against external factors in this application. It is famous for its strength, durability, and chemical resistance.

Aerospace industry

Professionals in the aerospace industry use UV-activated glue for bonding components and sealing and coating applications. The industry commonly chooses this adhesive for its high strength and durability, which make it a reliable choice in this demanding field.