UV Adhesives and Sealants

Deepmaterial manufacturing ultra-violet light cure adhesive

products are used for various of industries.

Custom UV adhesives, glues and epoxies for your requirements.

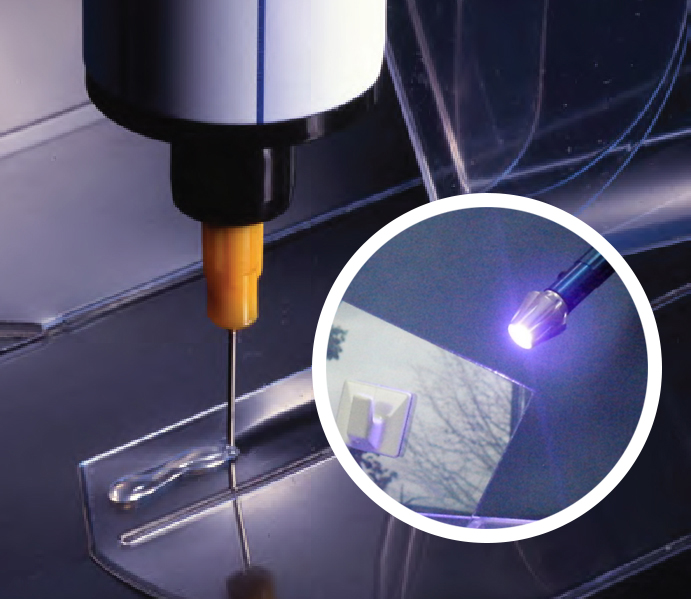

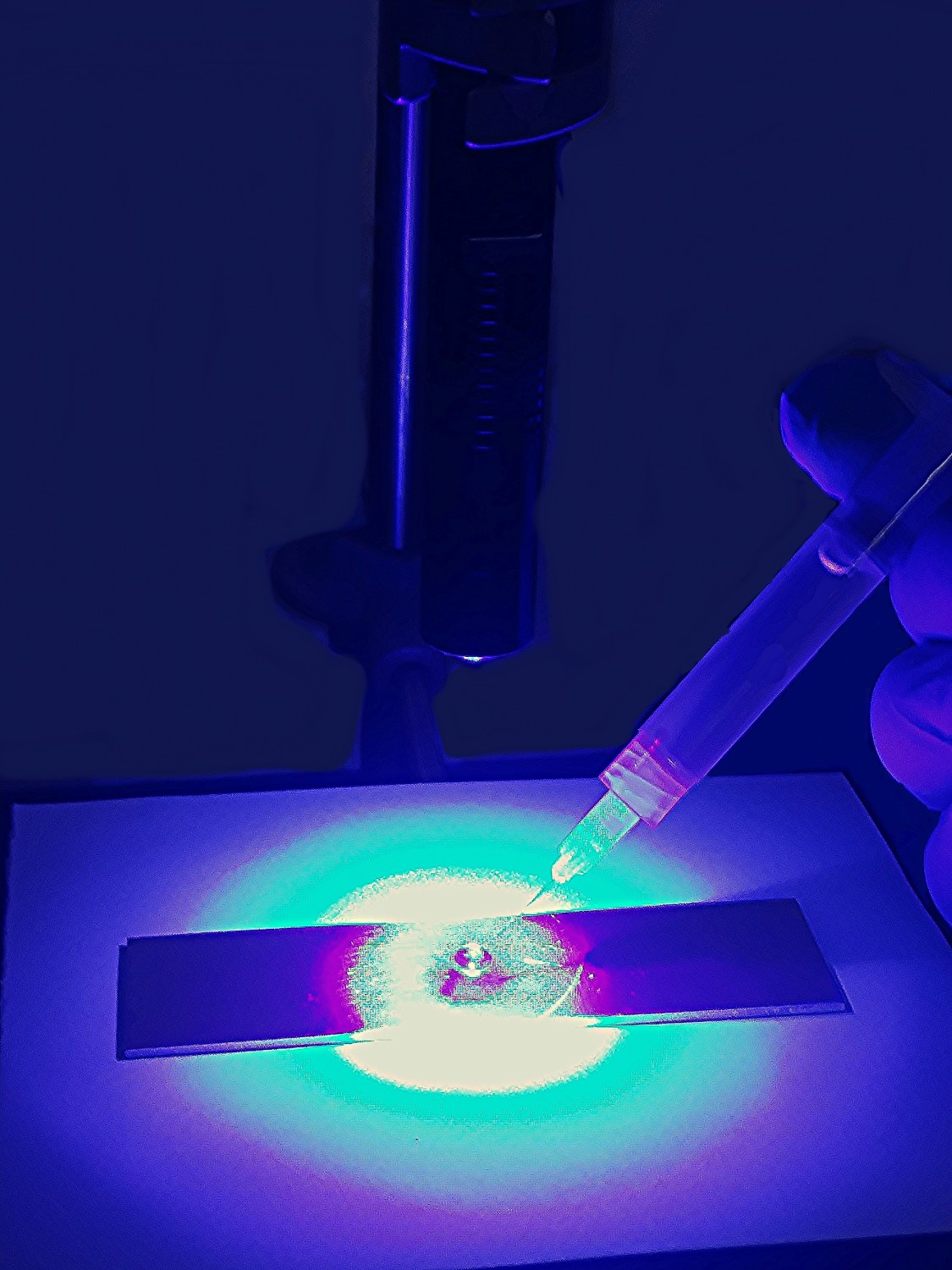

During the curing process, UV light sources are used to initiate the process. These adhesives are also known as light curing adhesives. Their bonds are usually transparent and colourless. UV adhesives are used for processes that require a high degree of precision. These include applications in the optical, medical, and electronics industries. They are also used in the production of glassware.

UV adhesives can be used for coating, potting, and sealing. Due to their fast cure time, they can produce large quantities. In addition, they are ideal for manual assembly since they do not cure until they are exposed to light, allowing the user to adjust the parts before they are bonded. Adhesives that use UV light are resistant to adverse environmental conditions such as humidity and sunlight.

Our UV adhesives are compatible with ceramics, concrete, composite materials, glass, fabric, metal, paper, polycarbonate, plastic, PVC, wood, rubber, and more. After being exposed to long-wave ultraviolet light and/or visible light, these UV-curable adhesives dry in seconds or less. With Deepmaterial adhesives, UV light initiates the curing process and forms a permanent bond without the need for heating. High-speed applications are best suited to Deepmaterial adhesives.

Advantages of Deepmaterial UV Curable Adhesives

- Bonds with high strength

- Choose a Cure Speed – Simply add another lamp to double production speed.

- Only cures when exposed to light – Allows parts to be aligned before bonding.

- It is a single-part product – no mixing is required

- Non-flammable – Solvent-free – increase safety

- Energy-saving – Epoxy heat cure ovens consume more electricity than UV lamps

- 100% solids – No waste.

- Appearance – UV glue comes in a colorless, clear formulation

- Space savings – UV lamps take up less space than heat curing ovens

- Technical Support – Adhesive selection and production process assistance available from application specialists.

Types of UV Adhesives/Light Cure Adhesives and Sealants

Consider whether the UV adhesive has a UV-only or UV-plus visible photoinitiator system. The substrate should then be examined to determine its transmission characteristics. It is not possible to use a product that contains only a UV photoinitiator on a substrate that transmits visible light but not UV light (that is, is UV opaque). In a substrate that transmits UV and visible light, any source will be able to cure a product, although the main concern is cure speed, which is determined by the intensity of light.

With UV light curing adhesives and sealants, you can ensure optimal adhesion to a variety of substrates and processes. Each UV-curing acrylic adhesive and sealant is capable of adhering to a broad range of substrates, while displaying properties to ensure flexibility in use. UV acrylic and silicone adhesives are available, as well as LED curing adhesives, which have unique properties. When substrates do not transmit UV wavelengths, this type of adhesive provides an alternative to conventional UV adhesives and sealants. Furthermore, these adhesives offer excellent optical clarity, making them an excellent choice for optical applications.

No matter what industry you are in, Deepmaterial balances the following features to meet your specific application needs:

- High strength

- High cure speeds

- Excellent stability

- On-demand curing

- High transparency

- High viscosity

- High precision

UV/Light Cure Acrylic Adhesives and Sealants

Despite the solvent-free nature of single component formulations, they cure in seconds when exposed to sunlight. There are three main components of light cure acrylics: the photoinitiator, monomer, and oligomer. Furthermore, UV acrylic adhesives maintain reliable adhesion to substrates including ABS, acrylic, HDPE, PP, and more thanks to their highly flexible adhesion properties.

LED Curing Adhesives and Sealants

Unlike UV curing adhesives, LED curing adhesives don’t require mixing and can be cured in seconds when illuminated by LEDs. While retaining many of the excellent properties of UV cure formulations, they are also more environmentally friendly and safer to use. It is also possible to use them as gap fillers in thicker sections than those cured with UV light.

UV/Light Cure Silicone Adhesives and Sealants

The UV cure silicones come in a range of viscosities to ensure flexibility across a wide range of applications. UV cure silicones combine ultra-fast curing speeds with excellent temperature resistance. It can also be used in a range of challenging conditions on a range of substrates because it is highly resistant to oxygen, ozone, UV light, aging, weather, and chemicals.

Industrial Applications for UV/Light Cure Adhesives and Sealants

Adhesives and sealants that cure with UV light can be used across a wide variety of industries. However, they are frequently found within plastic and glass components. By applying the specified UV light range to glass adhesives, manufacturers are able to bond materials with an extremely high degree of control and in ultra-quick times.

Due to their excellent properties, including speed of cure and exceptional stability, Deepmaterial’s UV cure adhesives and sealants are used in a wide range of industrial applications. Deepmaterial products are the UV cure adhesive of choice for prominent manufacturers around the world because of these and other benefits.

In both the medical and electronics industries, UV adhesives and sealants fulfill a variety of functions that require superior environmental resistance, a wide operating temperature range, low shrinkage, and strong, tack-free finishes in manufacturing processes. Additionally, they may be used in the following industries:

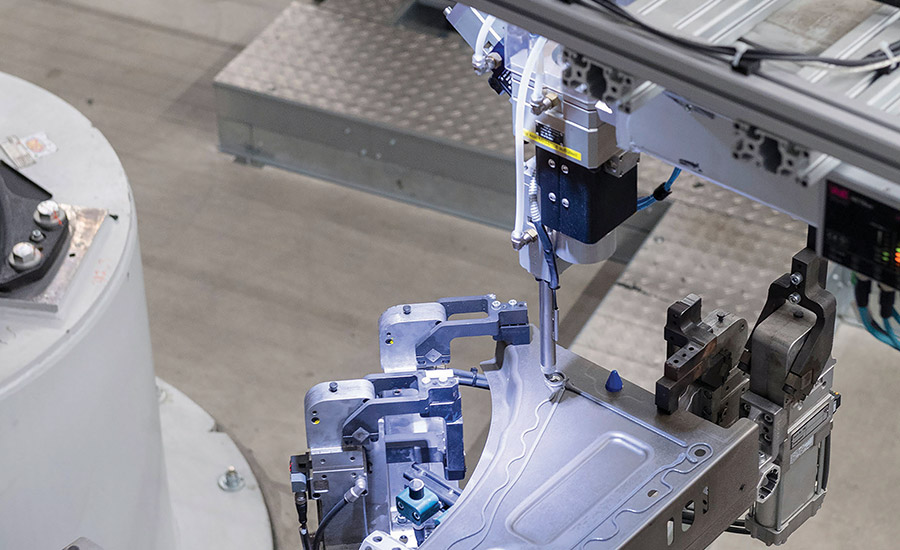

Automotive Adhesives

Dentistry Adhesives

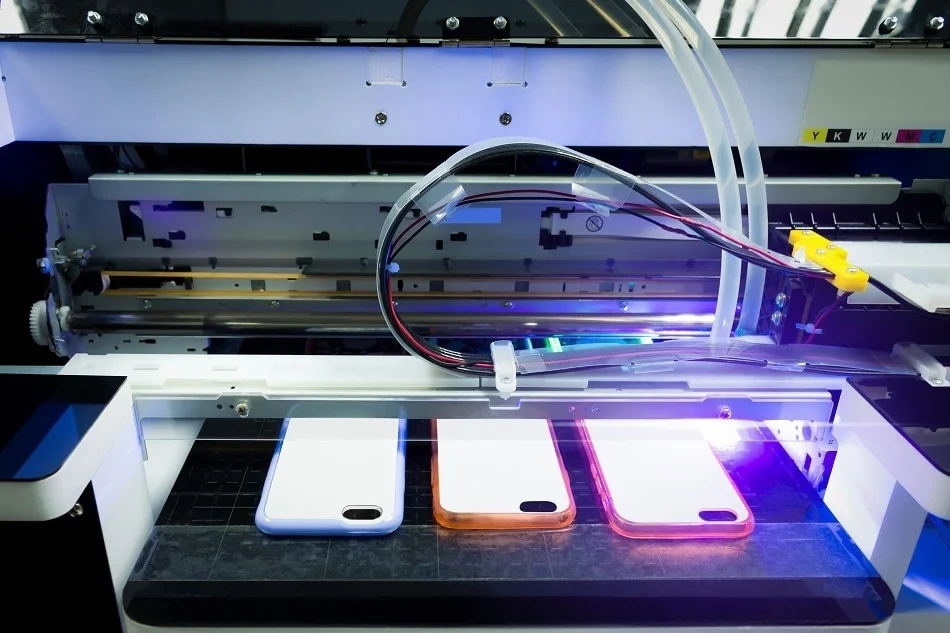

Printing Adhesives

Electronics Industry

Due to the miniaturization of today’s electronics and the predicted growth of automotive electronic systems like ADAS, UV cure adhesives and sealants are ideal for the automotive industry. The application of UV cure adhesives and sealants during manufacturing can enhance the stability, strength, and environmental resistance of electronic displays. In addition, smaller components such as speakers and microphones in handheld devices that require plastic bonding may benefit from this type of adhesive, while printed circuit boards in other consumer electronics often use light cure adhesives.

Medical Industry

The medical industry faces two challenges. It is necessary to adhere substrates accurately and quickly when performing precision manufacturing processes. In addition, medical facilities of all types must meet high standards for compliance. UV cure adhesives manufactured to medical grade meet this challenge by ensuring fast curing and high resistance.

We offer a wide range of high-performance, light curing medical device UV adhesives designed specifically for production of medical equipment and items such as syringes, catheters, and blood filters. As with medical components, these UV cure adhesives are tested using the same techniques for licensing and certified in accordance with ISO 10993, the internationally accepted standard for testing adhesives.