UV curable polyurethane adhesive is a powerful adhesive that offers several advantages over traditional adhesive systems. It is a fast-curing, high-performance adhesive widely used in many industries due to its superior bonding capabilities, reduced environmental impact, and increased efficiency. This blog post will discuss the different aspects of UV-curable polyurethane adhesive, including its benefits, applications, and usage guidelines.

WHAT IS UV-CURABLE POLYURETHANE ADHESIVE?

Definition

UV-curable polyurethane adhesive is a type of adhesive that hardens rapidly upon exposure to ultraviolet (UV) light. It is a two-component adhesive system that consists of a resin and a hardener.

Composition

The resin component of UV-curable polyurethane adhesive comprises oligomers, monomers, and photo-initiators, while the hardener component contains a mixture of isocyanates and other additives. The photo-initiators in the resin component are activated by UV light, triggering a polymerization reaction that hardens the adhesive when mixed with the two parts.

Working Mechanism

UV-curable polyurethane adhesive works by utilizing the energy from UV light to initiate a polymerization reaction that hardens the cement. This mechanism ensures that the adhesive cures rapidly, forming a solid bond between the substrates.

Benefits of UV Curable Polyurethane Adhesive

Rapid Curing Time

One of the most significant advantages of UV-curable polyurethane adhesive is its rapid curing time. Unlike traditional bonds that may take hours or days to cure, UV-curable polyurethane adhesive cures in seconds upon exposure to UV light. This quick curing time can significantly reduce production time and increase productivity, resulting in cost savings.

Increased Bond Strength

UV curable polyurethane adhesive offers superior bonding strength compared to traditional adhesives. Its unique composition allows it to penetrate deep into the substrate’s surface, creating a solid and durable bond. This increased bond strength is essential in industries such as automotive and aerospace, where the adhesive must withstand high stress and tension.

Reduced Environmental Impact

UV-curable polyurethane adhesive is a more environmentally friendly option than traditional adhesives. Unlike solvent-based adhesives that release volatile organic compounds (VOCs) into the atmosphere, UV-curable polyurethane adhesive emits no harmful substances. Therefore, it reduces the environmental impact and ensures a safer working environment for employees.

Compatibility with Various Substrates

UV-curable polyurethane adhesive is compatible with many substrates, including metals, plastics, ceramics, and glass. This versatility makes it popular in various industries, as it can quickly bond different materials.

Improved Production Efficiency

The rapid curing time and increased bond strength of UV-curable polyurethane adhesive lead to improved production efficiency. Because UV-curable polyurethane adhesive can cure in seconds, it reduces the need for additional production steps, such as clamping or waiting for the glue to dry. This reduction in steps increases throughput and reduces production time, resulting in cost savings.

Enhanced Durability and Reliability

UV-curable polyurethane adhesive is highly durable and reliable, ideal for high-stress applications. Its ability to withstand extreme temperatures, moisture, and chemical exposure ensures the bond remains intact over an extended period. This enhanced durability and reliability make UV-curable polyurethane adhesive popular in the construction, aerospace, and electronics industries.

Applications of UV Curable Polyurethane Adhesive

Many industries use UV-curable polyurethane adhesive due to its numerous benefits. Typical applications of UV-curable polyurethane adhesive include:

Automotive Industry

The automotive industry commonly uses UV-curable polyurethane adhesive to bond various automotive components, including headlights, taillights, interior trim, and exterior parts. Its ability to cure quickly and provide a strong bond makes it a preferred adhesive for automotive manufacturers.

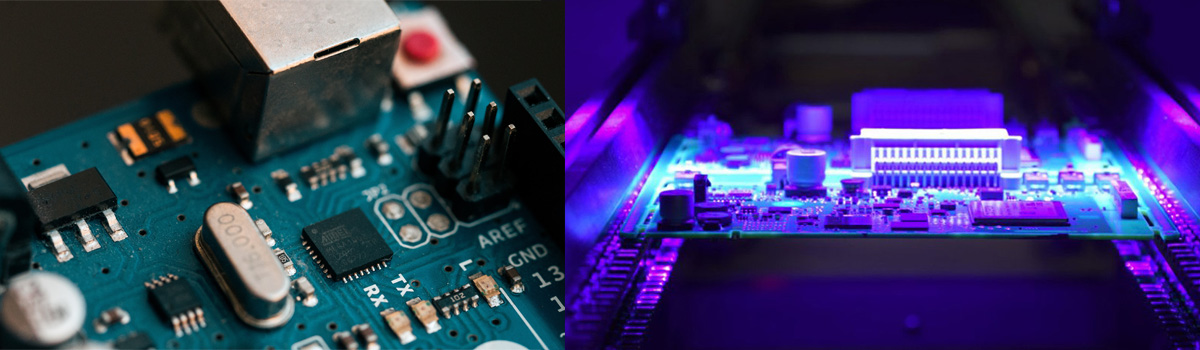

Electronics Industry

The electronics industry uses UV-curable polyurethane adhesive to encapsulate and bond electronic components. Its low-temperature curing process is suitable for heat-sensitive parts, and its high bond strength and durability provide long-lasting protection to electronic devices.

Medical Industry

The medical industry uses UV-curable polyurethane adhesive to bond and seals medical devices and implants. Its biocompatibility and ability to cure without heat make it an ideal adhesive for medical applications.

Construction Industry

The construction industry uses UV-curable polyurethane adhesive for bonding and sealing various building components, including glass, metal, and wood. Its ability to provide strong bonding even on porous surfaces and its resistance to weathering and chemicals make it a preferred adhesive for construction.

Aerospace Industry

The aerospace industry uses UV-curable polyurethane adhesive for bonding and sealing aircraft components, such as wings, fuselages, and interior parts. Its ability to provide a high-strength bond, durability, and resistance to extreme temperatures and chemicals makes it a suitable adhesive for aerospace applications.

Consumer Goods Industry

The consumer goods industry commonly uses UV-curable polyurethane adhesive to bond various products, including furniture, footwear, and toys. Its ability to provide a strong bond, resistance to heat and chemicals, and quick curing time makes it a popular adhesive in the consumer goods industry.

How to Use UV Curable Polyurethane Adhesive

Following proper usage, guidelines are necessary to ensure the maximum effectiveness of UV-curable polyurethane adhesive. Outlined below are the steps for using UV-curable polyurethane adhesive appropriately:

Surface Preparation

Following proper usage, guidelines are necessary to ensure the maximum effectiveness of UV-curable polyurethane adhesive. It is essential to clean and dry the surface to be bonded and ensure it is free of dust, grease, or other contaminants. Removing any loose or flaking material and priming the surface is essential.

Adhesive Application

To ensure an even application, one should apply the adhesive uniformly to one of the surfaces intended for bonding using a brush, roller, or spray. The substrates should be aligned and pressed with adequate pressure to ensure a strong bond.

Curing Process

The curing process of UV-curable polyurethane adhesive involves exposing the adhesive to UV light of the appropriate wavelength and intensity. The curing time may vary depending on the adhesive’s thickness, the power of the UV light, and the substrate material.

Post-Curing Process

After the adhesive has cured, it may undergo post-curing to improve its mechanical and chemical properties. Expose the adhesive to heat, humidity, or chemical treatment to perform post-curing.

UV-curable polyurethane adhesive is a reliable and efficient solution for enhancing bonding quality and efficiency in various industries. Its superior bonding capabilities, reduced environmental impact, and enhanced durability and reliability make it a popular choice for numerous applications. However, following the proper usage guidelines when working with UV-curable polyurethane adhesive is essential to ensure its maximum effectiveness. By taking advantage of its benefits and following the appropriate usage guidelines, industries can enhance their bonding capabilities and achieve greater efficiency and productivity.