UV cure silicone adhesive is a versatile, high-performance adhesive that has been gaining popularity in various industries. With its unique properties and fast curing time, UV cure silicone adhesive has become an essential tool for many businesses and professionals. This post will explore what UV cure silicone adhesive is, how it works, its benefits, and its applications. We will also provide tips for choosing the suitable UV cure silicone adhesive and using it effectively.

What is UV Cure Silicone Adhesive?

Manufacturers cure UV cure silicone adhesive, a type of adhesive, using ultraviolet light. It is a two-component system consisting of a base and a curing agent. The floor is typically silicone, and the curing agent is a photoinitiator that reacts to UV light. When the two components are mixed, they react and form a strong bond.

How it works:

UV cure silicone adhesive works by initiating a chemical reaction when exposed to UV light. The photoinitiator in the curing agent absorbs the UV light and starts the curing process. Curing occurs quickly, typically in seconds, producing a solid and durable bond.

Chemical composition:

The chemical composition of UV cure silicone adhesive varies depending on the manufacturer and the specific application. However, most UV-cure silicone adhesives consist of a base of silicone and a curing agent containing a photoinitiator. The photoinitiator reacts to UV light and initiates the curing process.

Benefits of UV Cure Silicone Adhesive

Fast curing time:

One of the primary benefits of UV cure silicone adhesive is its fast curing time. Unlike other bonds, which can take hours or even days to cure, UV-cure silicone adhesive cures in seconds. UV-cure silicone adhesive makes it an ideal choice for applications that require a fast cure time, such as electronics and automotive manufacturing.

Durability and strength:

UV-cure silicone adhesive produces a strong and durable bond. It is resistant to temperature and moisture, making it ideal for applications in harsh environments. It is also flexible, which allows it to absorb shock and vibration without breaking the bond.

Temperature and moisture resistance:

UV cure silicone adhesive is resistant to temperature and moisture, making it ideal for applications in harsh environments. It can withstand high temperatures and exposure to water, making it a perfect choice for outdoor applications.

Flexibility and versatility in application:

One can use UV-cure silicone adhesive in various applications as it is versatile. It is flexible, which allows it to absorb shock and vibration without breaking the bond. One can use it on multiple surfaces, such as metals, plastics, and glass.

Applications of UV Cure Silicone Adhesive

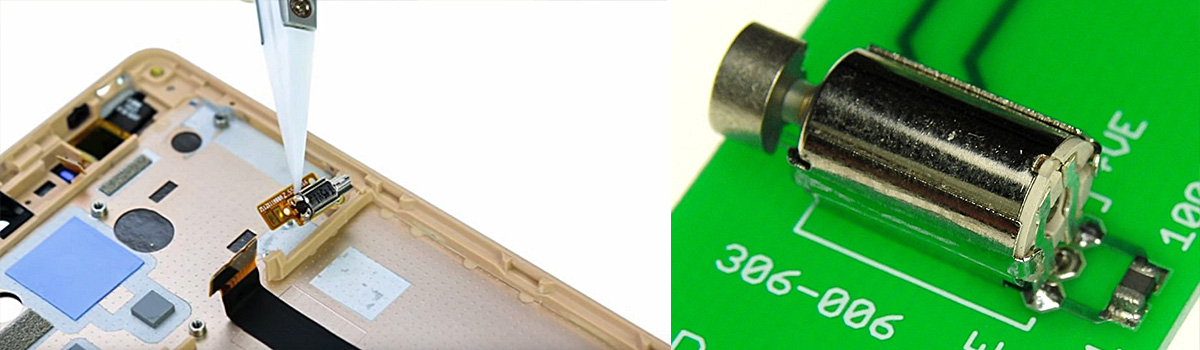

Electronics and electrical industries:

The electronics and electrical industries widely use UV-cure silicone adhesive. It bonds electronic components, such as circuit boards and sensors, and it also seals and protects electronic components from moisture and other environmental factors.

Automotive and aerospace industries:

The automotive and aerospace industries also use UV-cure silicone adhesive. Manufacturers use it to bond and seal various components such as windshields, headlights, and engine components. It also bonds and seals aircraft components, such as windows and fuselage panels.

Medical and dental industries:

UV cure silicone adhesive is used in the medical and dental industries to bond and seal medical devices, such as catheters and pacemakers. It is also used in dental applications to connect and fill dental restorations, such as crowns and bridges.

Construction and building industries:

UV cure silicone adhesive is used in the construction and building industries to bond and seal various materials, such as glass, metal, and plastic. It also connects and seals structural elements, such as beams and columns.

Choosing the Right UV Cure Silicone Adhesive

Factors to consider when choosing UV cure silicone adhesive:

When choosing UV-cure silicone adhesive, there are several factors to consider. Considering factors such as the application, bonded materials, and environmental conditions, one should consider the needs of where they will use the adhesive. Select a sealant compatible with the related materials that can withstand environmental conditions.

Understanding viscosity, hardness, and other vital properties:

Viscosity and hardness are two fundamental properties when choosing UV-cure silicone adhesive. The thickness of the bond, known as viscosity, can impact the ease of its flow and the required amount for a specific application. Hardness refers to the strength of the cured adhesive and can affect the durability of the bond.

Selecting the appropriate curing equipment:

UV cure silicone adhesive requires a UV light source for curing. He is choosing the appropriate curing equipment for the specific application, including handheld UV lights, conveyor belt systems, or other specialized equipment.

Using UV Cure Silicone Adhesive Effectively

Best practices for handling and storing UV cure silicone adhesive:

UV-cure silicone adhesive should be stored in a cool, dry place to prevent exposure to heat and moisture. It should also be kept in its original container and sealed tightly to prevent contamination. Following the manufacturer’s instructions for handling and storing the adhesive is essential.

Tips for preparing surfaces for bonding:

Before applying UV-cure silicone adhesive, surfaces should be clean and free from dirt, grease, and other contaminants. Surfaces should also be dry before applying the glue, and it may be necessary to use a primer or other surface treatment to improve the bond strength.

Guidelines for curing and post-curing:

UV cure silicone adhesive requires a specific amount of UV light exposure for curing and following the manufacturer’s instructions for fixing time and intensity is essential. After curing, the bond may require post-curing to ensure full strength and durability.

Where to Find UV Cure Silicone Adhesive

Online suppliers and distributors:

There are many online suppliers and distributors of UV cure silicone adhesives. These companies offer a wide range of products and can provide technical support and guidance on selecting a suitable adhesive for a specific application.

Trade shows and exhibitions:

Trade shows and exhibitions provide an excellent opportunity to stay up-to-date with the advancements in technology for curing silicone adhesives. At these events, manufacturers, distributors, and industry experts come together to showcase new products and technologies. These events bring together manufacturers, distributors, and industry experts to showcase the latest products and technologies.

Referrals from industry experts:

Industry experts, such as engineers and consultants, can provide valuable insights and recommendations on selecting the suitable UV cure silicone adhesive for a specific application. They can also provide guidance on best practices for handling and using the glue.