In various industries, bonding glass to metal is a crucial process. It is vital to ensure that the bond between the glass and metal is solid and durable to maintain the integrity of the structure or device. In recent years, UV bonding has emerged as a popular technique for glass-to-metal bonding. UV bonding offers several advantages over traditional bonding methods, including high bonding strength, transparency, clarity, temperature and moisture resistance, and flexibility in application. This blog post will provide a comprehensive guide to UV bonding glass to metal, including what UV bonding is, its benefits, applications, and tips for choosing the suitable UV bonding adhesive and using it effectively.

What is UV Bonding?

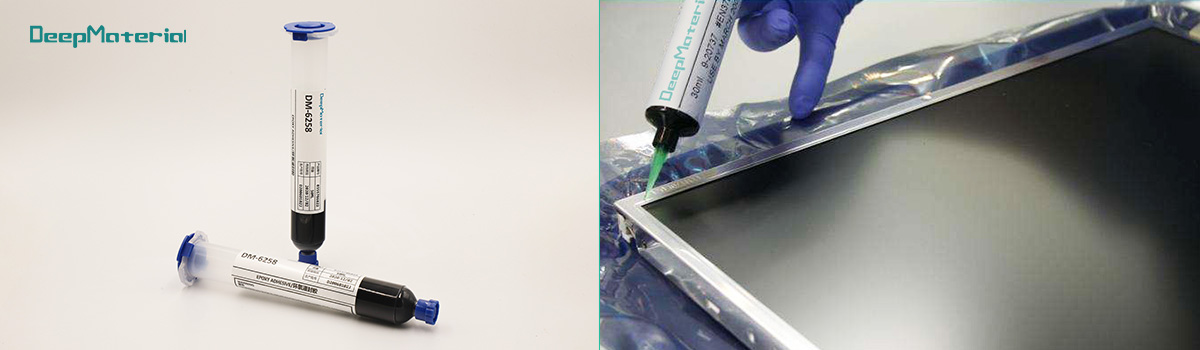

UV bonding is a technique that uses ultraviolet light to cure a specially formulated adhesive, creating a solid bond between two surfaces. The glue used in UV bonding is typically a liquid or gel that contains photoinitiators. Photoinitiators are compounds that react to UV light and initiate the curing process of the adhesive.

In the UV bonding process, one of the surfaces is coated with the adhesive and brought into contact with the other surface. Then, a UV light source activates the photoinitiators in the glue, causing it to harden and create a strong bond between the two characters.

The chemical composition of UV bonding adhesive can vary depending on the specific application. Most manufacturers use acrylic or epoxy resins as the basis for UV bonding adhesives because they offer excellent bonding strength and durability.

Benefits of UV Bonding Glass to Metal

UV bonding offers several benefits over traditional bonding methods regarding glass-to-metal bonding.

- High bonding strength: By penetrating the glass and metal surface, UV bonding creates a solid and durable bond between them, forming a mechanical bond that is difficult to break.

- Transparency and clarity:UV bonding with a transparent adhesive does not leave any residue or discoloration on the bonded surfaces, resulting in a fine bond line that does not interfere with the appearance of the glass or metal.

- Temperature and moisture resistance:Manufacturers design UV bonding adhesives to withstand high temperatures and exposure to moisture, making them ideal for use in harsh environments where traditional bonding methods may fail.

- Flexibility and versatility in application: UV bonding is a versatile and flexible bonding technique that can bond a wide range of materials, including glass to metal, glass to glass, metal to metal, and plastic to plastic.

Applications of UV Bonding Glass to Metal

Industries widely use UV bonding for glass-to-metal bonding in various applications, including:

- Automotive and aerospace industries: Cars, trucks, and airplanes use UV bonding to bond glass windows and panels to metal frames. It also bonds interior components, such as instrument panels and control systems.

- Electronics and display manufacturing: Electronic device manufacturers use UV bonding to bond glass screens to metal frames, including those in smartphones, tablets, and computer monitors. It also bonds displays in industrial control systems and medical equipment.

- Medical and laboratory equipment: Manufacturers use UV bonding to bond glass components in medical and laboratory equipment, such as microscopes, pipettes, and syringes.

- Construction and building industries:Commercial and residential contractors use UV bonding to bond glass windows and panels to metal frames. It also bonds glass components in furniture and interior design elements.

Choosing the Right UV Bonding Adhesive

Choosing the suitable UV bonding adhesive ensures a strong and durable bond between glass and metal. Here are some factors to consider when selecting a UV bonding adhesive:

- Surface compatibility: The adhesive must be compatible with the bonded glass and metal surfaces. It is essential to consider both materials’ surface energy and chemical composition to ensure the adhesive will bond properly.

- Viscosity and hardness:The thickness and hardness of the adhesive will affect its flow and cure time. Selecting a bond with the proper consistency and hardness for the specific application is essential.

- Curing equipment: The equipment used will also affect the bonding process. It is essential to select the appropriate curing equipment based on the adhesive and the size of the bonded surfaces.

Using UV Bonding Adhesive Effectively

UV bonding adhesive is crucial for achieving a solid and durable bond between glass and metal. Here are some best practices for handling and using UV bonding adhesive:

- Handling and storing: UV bonding adhesive should be stored in a cool, dry place and handled carefully to prevent contamination. Following the manufacturer’s instructions for handling and keeping the glue is essential.

- Surface preparation:Before applying the adhesive, you should clean the surfaces bonded with a solvent or alcohol to ensure they are clean, dry, and free of contaminants, such as oil or dust.

- Curing and post-curing:The UV light’s curing time and intensity will affect the bond’s strength. Following the manufacturer’s instructions for fixing and post-curing the adhesive is essential to ensure a strong bond.

Where to Find UV Bonding Adhesive for Glass to Metal

Various suppliers and distributors offer UV bonding adhesive for glass to metal. Some of the sources are:

- Online suppliers: There are many online suppliers of UV bonding adhesive for glass to metal. It is essential to research the supplier and the product before purchasing.

- Trade shows and exhibitions: Trade shows and exhibitions are a great way to learn about new products and technologies in the industry. Attendees can meet with suppliers and distributors and learn about the latest products and services.

- Referrals from industry experts:Industry experts and professionals can provide valuable referrals for suppliers and distributors of UV bonding adhesive for glass to metal.

UV bonding is a versatile and effective technique for bonding glass to metal. It offers several advantages over traditional bonding methods, including high bonding strength, transparency and clarity, temperature and moisture resistance, and flexibility in application. Selecting the suitable UV bonding adhesive and using it effectively are crucial for achieving a solid and durable bond between glass and metal. Businesses and professionals can ensure their structures and devices are stable and reliable by investing in high-quality UV bonding adhesives.