UV adhesive glue is a type of adhesive that is cured or set under ultraviolet (UV) light. It has become increasingly popular in recent years due to its unique properties, such as fast curing time, high bond strength, and versatility.

This post will explore everything you need to know about UV adhesive glue, including its types, uses, benefits, and drawbacks.

What is UV Adhesive Glue?

Definition and Explanation

UV adhesive glue is a type of adhesive that is cured or set under ultraviolet light. This type of glue typically consists of a base resin and a photoinitiator. When exposed to UV light, the photoinitiator initiates a chemical reaction that causes the resin to cure or set, creating a solid bond.

Types of UV Adhesive Glue

There are several types of UV adhesive glue available, including:

- Acrylic-Based UV Adhesive: This UV adhesive glue is ideal for bonding plastics, metals, and glass. It offers high bond strength and is resistant to chemicals and temperature changes.

- Epoxy-Based UV Adhesive:This type of UV adhesive glue is ideal for bonding metals, ceramics, and glass. It offers high bond strength and is resistant to temperature changes and chemicals.

- Silicon-Based UV Adhesive:This UV adhesive glue is ideal for bonding silicone, rubber, and plastics. It offers good adhesion and flexibility.

- Polyurethane-Based UV Adhesive:This UV adhesive glue is ideal for bonding metals, plastics, and glass. It offers high bond strength and is resistant to temperature changes and chemicals.

Uses of UV Adhesive Glue

Automotive Industry

UV adhesive glue is commonly used in the automotive industry for bonding and sealing applications. It can bond various materials, including plastics, glass, and metals.

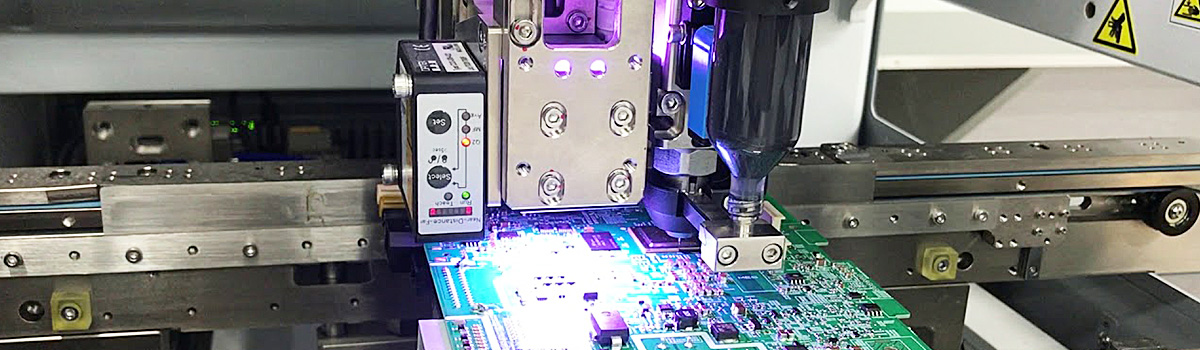

Electronics Industry

UV adhesive glue is also used in the electronics industry for bonding and sealing applications. It can bond and seal components, such as microchips and circuit boards.

Medical Industry

UV adhesive glue is commonly used in the medical industry for bonding and sealing applications. It can bond and seal medical devices, such as catheters and implants.

Aerospace Industry

UV adhesive glue is also used in the aerospace industry for bonding and sealing applications. It can bond and seal aircraft components, such as panels and windows.

Construction Industry

UV adhesive glue is commonly used in the construction industry for bonding and sealing applications. It can bond and seal various materials like glass, metal, and plastic.

Jewelry Making and Repair

UV adhesive glue is also used in the jewelry industry for bonding and repair applications. It can be used to bond and repair various types of jewelry, such as rings and bracelets.

Advantages of UV Adhesive Glue

While UV adhesive glue has some drawbacks, it has several advantages that make it a popular choice for various industries and applications. Here are some of the critical benefits of UV adhesive glue:

Fast Curing Time

One of the most significant advantages of UV adhesive glue is its fast curing time. Unlike traditional bonds that require several hours or even days to cure, UV adhesive glue can cure in seconds when exposed to UV light. This makes it an ideal choice for applications that require fast bonding and quick turnaround times.

High Bond Strength

UV adhesive glue offers excellent bond strength, often exceeding the strength of bonded materials. This makes it suitable for applications requiring high-strength bonding, such as aerospace and automotive industries.

Versatility

UV adhesive glue can bond various materials, including plastics, metals, glass, ceramics, and composites. This makes it a versatile adhesive that can be used for multiple applications.

Waterproof

UV adhesive glue is waterproof and resistant to moisture, making it ideal for applications that require water-resistant bonding, such as in the marine industry.

Resistant to Temperature and Chemicals

UV adhesive glue is also resistant to temperature and chemicals, making it suitable for applications that require bonding under extreme conditions. It can withstand high and low temperatures and exposure to chemicals and solvents.

Disadvantages of UV Adhesive Glue

Despite its many benefits, UV adhesive glue has some drawbacks when choosing an adhesive for your application. Here are some of the key disadvantages of UV adhesive glue:

Limited Working Time

One of the main disadvantages of UV adhesive glue is its limited working time. Once the adhesive is exposed to UV light, it begins to cure rapidly, leaving little time for adjustment or repositioning.

Special Equipment Required

UV adhesive glue requires special curing equipment, such as a UV light source. This can add to the cost of the adhesive and require additional setup time and resources.

Expensive Compared to Other Adhesives

UV adhesive glue can be more expensive than traditional adhesives, especially for small-scale applications. However, for large-scale applications that require fast curing and high bond strength, the benefits of UV adhesive glue may outweigh the cost.

Not Suitable for All Materials

UV adhesive glue may not be suitable for all materials, particularly those that are opaque or do not transmit UV light, and this can limit its use in some applications.

Tips for Using UV Adhesive Glue

UV adhesive glue requires proper techniques and safety precautions to ensure the best results. Here are some tips to keep in mind when using UV adhesive glue:

Safety Precautions

UV adhesive glue can harm your skin and eyes, so taking proper safety precautions is essential. Wear gloves and eye protection when handling the adhesive and using UV light. If the adhesive comes into contact with your skin, wash it off immediately with soap and water.

Proper Surface Preparation

The surface you’re bonding should be clean, dry, and free of any dirt, grease, or other contaminants that could affect the bond. Use an alcohol-based cleaner to prepare the surface for bonding.

Correct Application Techniques

Apply the adhesive sparingly, as a thin layer is needed for a strong bond. Use a syringe or applicator to apply the adhesive precisely where required. Then, firmly press the surfaces and hold them in place until the adhesive cures.

Choosing the Right Type of UV Adhesive Glue

Choosing the correct type of UV adhesive glue is critical for achieving the best results. Consider the materials you’re bonding, the application, and the curing time required. Consult with the manufacturer to ensure you select the suitable adhesive for your specific application.