UV glue is a popular adhesive with many applications, including glass-to-metal bonding. It is a versatile and easy-to-use adhesive that requires exposure to ultraviolet light to cure. It is perfect for applications where heat or pressure might damage the bonded materials. In this guide, we’ll take you through everything you need about using UV glue for glass-to-metal bonding, including preparation, application, and tips and tricks for success.

What is UV glue?

UV glue, or UV-cured adhesive, cures when exposed to ultraviolet light. It is a two-part adhesive that consists of a liquid resin and a photoinitiator. When UV light reveals the bond, the photoinitiator activates a chemical reaction that hardens and cures the liquid resin.

How does UV glue work?

UV glue uses ultraviolet light to initiate a chemical reaction that causes the adhesive to cure. Exposing the UV glue to UV light activates the photoinitiator and creates a chemical reaction, which causes the liquid resin to harden and cure. The result is a robust and durable bond resistant to heat, water, and other environmental factors.

Benefits of using UV glue for glass-to-metal bonding

There are several benefits to using UV glue for glass-to-metal bonding:

- UV glue is a fast-curing adhesive that can be cured in seconds, which makes it ideal for use in applications where time is of the essence.

- UV glue is resistant to heat, water, and other environmental factors, so it is suitable for harsh environments.

- UV glue is easy to use and requires no special tools or equipment.

Preparing the Surfaces

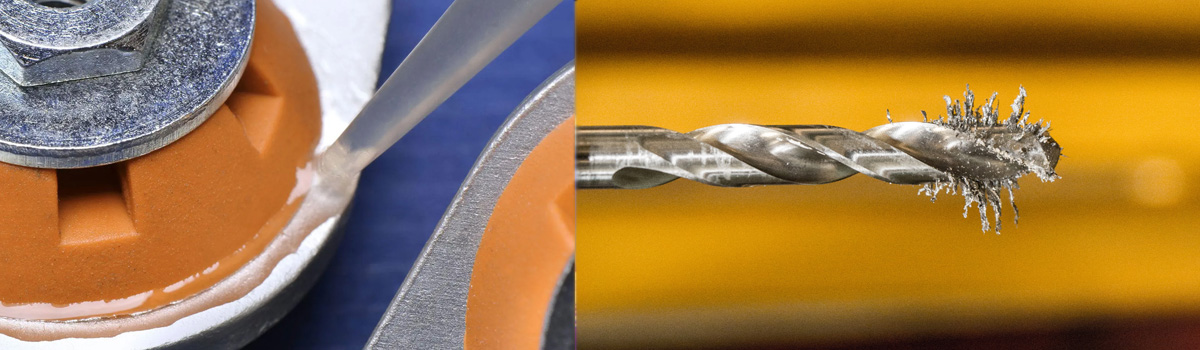

Cleaning the surfaces

The first step in preparing the surfaces for bonding is to clean them thoroughly. Any dirt, grease, or other contaminants on the surfaces can weaken the bond and reduce the effectiveness of the adhesive. To clean the surfaces, use a mild detergent, water, or a solvent such as isopropyl alcohol. Use a clean cloth to wipe the surfaces and ensure they are dehydrated before proceeding.

Sanding the surfaces (if necessary)

In some cases, sanding the surfaces may be necessary to create a rough texture that will help the adhesive bond better to the characters. Use fine-grit sandpaper to smooth the covers gently, taking care not to damage the materials. After sanding, clean the surfaces again to remove any dust or debris.

Applying a primer (optional)

In some cases, applying a primer to the surfaces before bonding can help to improve the bond strength. Before using the UV glue, a primer, which helps create a chemical bond between the textures and the adhesive, is applied to the surfaces, improving the overall bond strength. Scorch the primer according to the manufacturer’s instructions before using the UV glue.

Applying the UV Glue

Choosing the correct type of UV glue

Many different types of UV glue are available, and choosing the right style for your application is essential. Some kinds of UV glue are explicitly designed for glass-to-metal bonding and will provide the best results. When selecting a UV glue, consider factors such as bond strength, curing time, and environmental resistance.

Applying the glue to the surfaces

Apply the UV glue to one of the surfaces using a brush, syringe, or other applicators. Be careful not to apply too much glue, as this can cause the bond to be weaker. Use a spreader or roller to spread the glue evenly over the surface. Then, place the other cover on top of the glue and apply pressure to ensure good contact between the bodies. It is essential to work quickly and carefully when using the bond, as UV glue cures quickly once exposed to UV light.

Aligning the surfaces

Correctly aligning the surfaces is crucial for a solid and effective bond. Before applying any pressure, ensure that the characters are aligned correctly. If the covers are misaligned, carefully adjust them before applying pressure to provide a solid and even bond.

Curing the glue with UV light

After applying the glue and aligning the surfaces, the next step is to cure the adhesive using UV light. Use a UV lamp or flashlight to expose the adhesive to UV light, following the manufacturer’s instructions for the specific adhesive. It is essential to ensure the entire bond area is exposed to UV light to ensure the adhesive cures wholly and evenly.

Tips and Tricks for Success

Working with small parts

When working with small parts, applying the glue and correctly aligning the surfaces can be challenging. One helpful tip is to use a toothpick or other small tool to apply the glue to the characters, which will help ensure that the adhesive is applied evenly and accurately.

Using a UV flashlight

A UV flashlight can be a helpful tool when working with UV glue, and it allows you to cure the adhesive quickly and accurately, even in hard-to-reach areas. When using a UV flashlight, ensure the entire bond area is exposed to UV light to ensure the adhesive cures evenly.

Testing the bond strength

After the adhesive has cured, it is essential to test the bond strength to ensure it is strong enough for your application. Apply a gentle force to the bond to test its strength. If the bond is weak, it may be necessary to reapply the adhesive and cure it again with UV light.

UV glue is a powerful and effective adhesive that can create a solid and durable bond between glass and metal. Following the steps outlined in this guide, you can ensure your bond is reliable and long-lasting. Remember to choose the right type of UV glue, prepare the surfaces carefully, and use UV light to cure the glue. You can create professional-quality bonds lasting for years with practice and patience. UV glue is a versatile and easy-to-use adhesive with many applications beyond glass to metal bonding, making it a valuable addition to any DIY or professional toolkit.