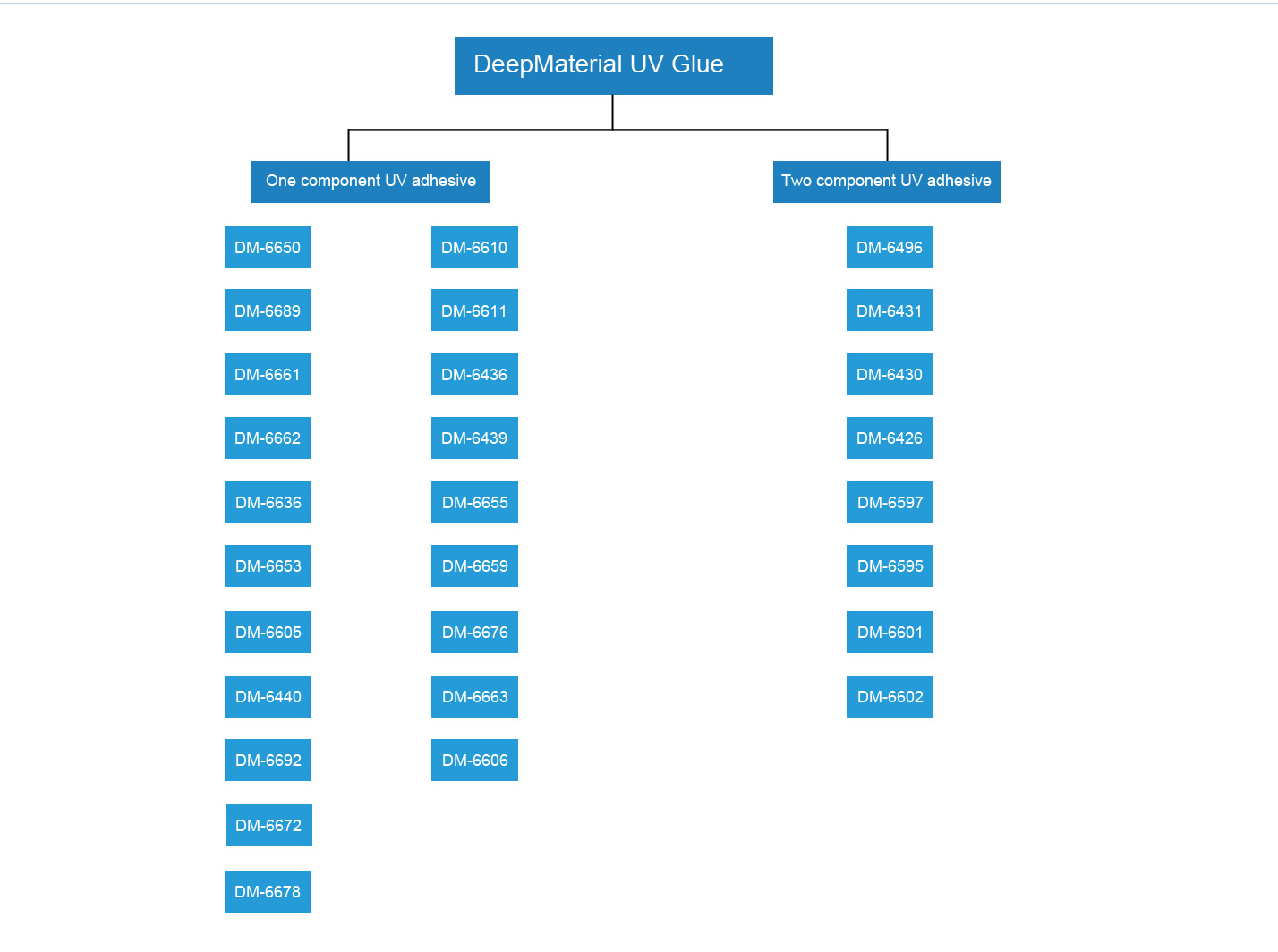

One component UV adhesives

Deepmaterial manufacturing custom

one component UV adhesives

Industrial one component UV adhesives

DeepMateriacl is the best industrial one component UV adhesives

Deepmaterial is a China industrial adhesive manufacturer specializing in (supplying) one component UV adhesives. With deep market and application knowledge, Deepmaterial’s experts are curious and passionate. We offer an unmatched portfolio of one component UV adhesives, sealants, and functional coatings that will help you transform markets and your business. We are your global partner, ready to tackle any challenge, and together, we will find a smart and sustainable solution.

UV Curing UV Adhesive

DeepMaterial UV Curing Adhesive

DeepMaterial’s UV-curing adhesive can quickly polymerize and cure under ultraviolet radiation, which helps to greatly improve production efficiency. Widely used in bonding, wrapping, sealing, reinforcing, covering and sealing purposes. DeepMaterial multi-purpose UV curing adhesive is a one-component solvent-free product, which can be cured in a few seconds under UV or visible light. It has a fast curing speed, high bonding strength, large curing depth, good toughness, and anti-yellowing.DeepMaterial adheres to the research and development concept of “market priority, close to the scene”, and strives to fully meet the current rapid development of electronic products, update the current situation of itera- tion, and continuously improve products, fully meet the requirements of high-speed assembly process of electronic products, and be compatible with solvent-free environmental protection technology, To ensure that customer’s production cost and efficiency are improved and the production concept of environmental protection and high efficiency is realized. The DeepMaterial multi-purpose UV curing adhesive product line covers the main applications of structural bonding. DeepMaterial multi-purpose UV curing adhesive in electronic compo- nents for temporary fixation, PCBA and port sealing, line coating and reinforcement, chip mount, protection and fixing coating, metal and glass high strength bonding, medical industry device bonding, component solder joints, LED Lamp strip bonding, horn film and coil bonding, camera focal length positioning /LENS bonding and other scenarios are widely used.

Advantages of UV curing adhesive

Ultraviolet curing technology can provide unique performance, design and process integration advantag- es:

Curing on demand

1.The adhesive is liquid before exposure to the UV system and can be cured within a few seconds of light

2.There is enough time before curing to allow precise positioning of the parts

3.Different curing systems determine different curing times and fast curing

4.Obtain an efficient production rate, so as to achieve the maximum production volume

5.Fast turnaround to ensure continuous production steps

Optical transparency

※Suitable for bonding clear and transparent substrates with a smooth surface

※Greatly broaden the choice of substrates

Quality assurance

※Using fluorescence characteristics to detect the presence of adhesive

※Fast curing to allow 100% online inspection ※Monitoring performance through curing parameters such as light intensity and light time

One-component system

※Automatic and precise dispensing

※No need for weighing and mixing, no operating time limit

※No solvent

Light Curing Adhesive Technology

1.Light-curing acrylic adhesives can provide the broad- est performance characteristics in all light-curing chemistries. Its optical transparency is comparable to glass and transparent plastics, and its universal bond- ing characteristics are its most notable feature.

2.The light-curing silicone adhesive can form a soft and tough thermosetting elastomer after curing, which has excellent elastic bonding, sealing and anti-leakage properties.

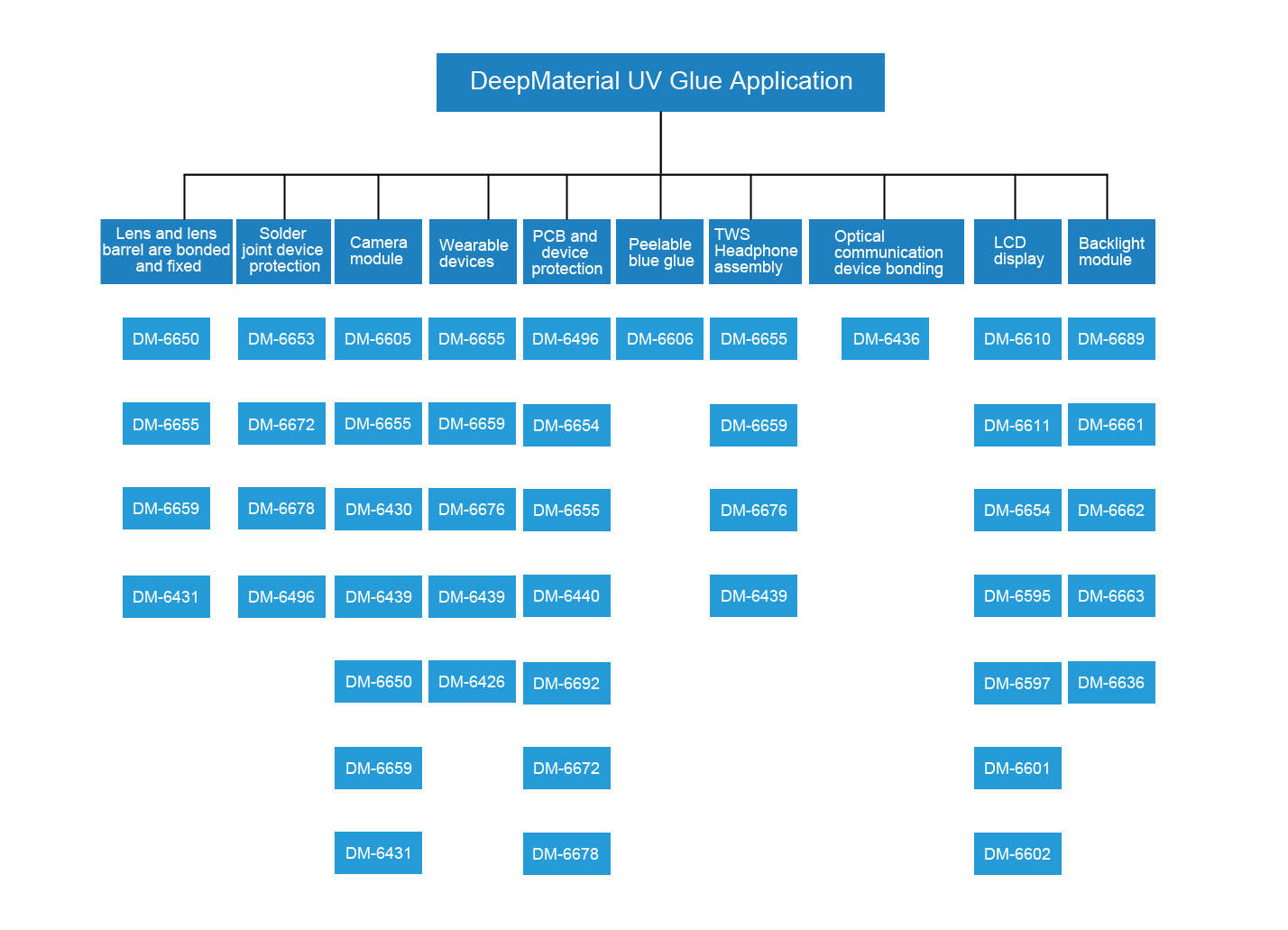

UV Curing Adhesive Applications

Electronic assembly applications in consumer electronics and industrial electronics, automotive electronics, communication electronics, and new light source industries need to provide high-reliability and adaptable adhesive products to adapt to ever-changing market needs.

DeepMaterial provides a comprehensive UV-cur- able adhesive product line for this purpose, including extremely transparent or translucent UV-curable adhe- sives for different scenarios, providing a targeted product line for LCD display, headset motor and other electronic accessories as well as machine assembly and other application scenarios; at the same time, for the medical industry, DeepMaterial provides a comprehensive solution. A dual-curing solution is provided for electrical protection at the circuit level and applications where a single curing cannot be used during assembly of the complete machine structure.

DeepMaterial adheres to the research and development concept of “market first, close to the scene”, and provides customers with comprehensive products, application support, process analysis and customized formulas to meet customers’ high-efficiency, low-cost and environmental protection requirements.

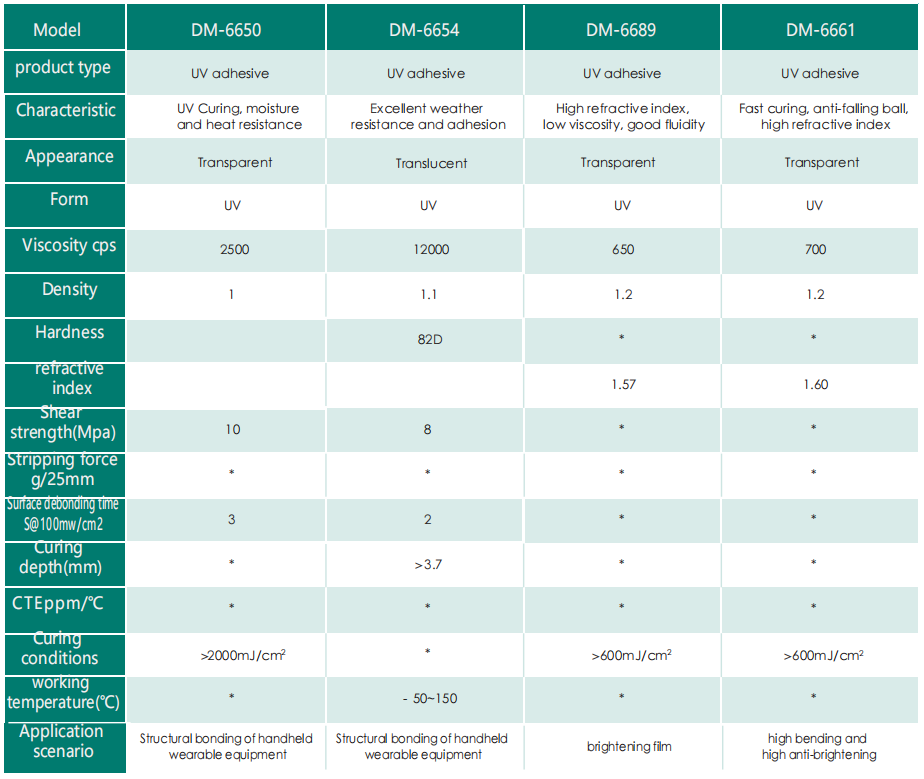

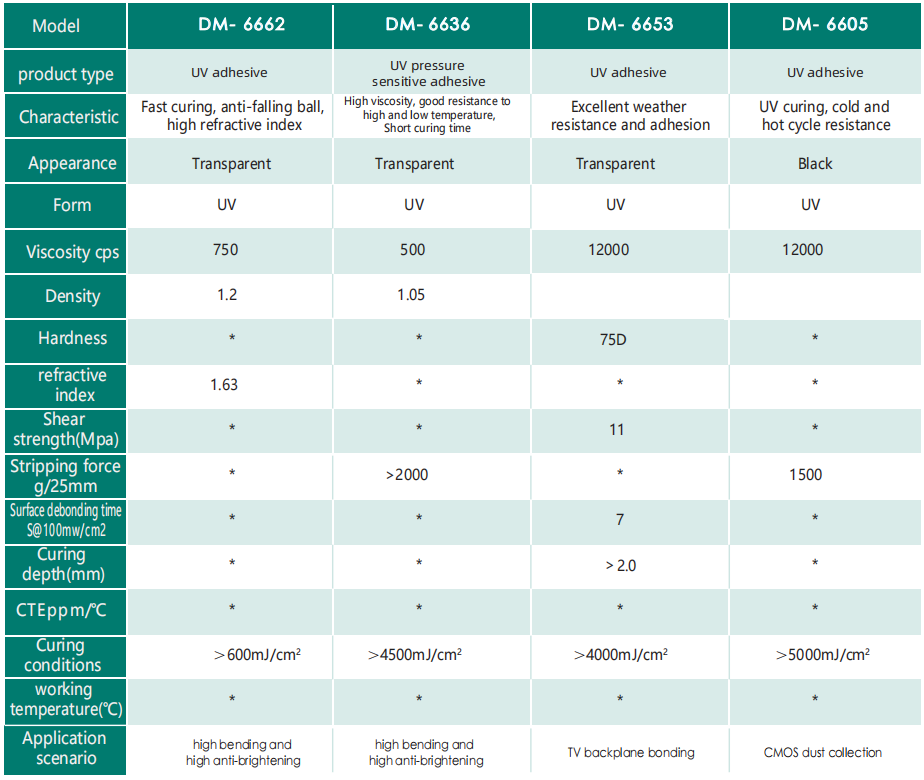

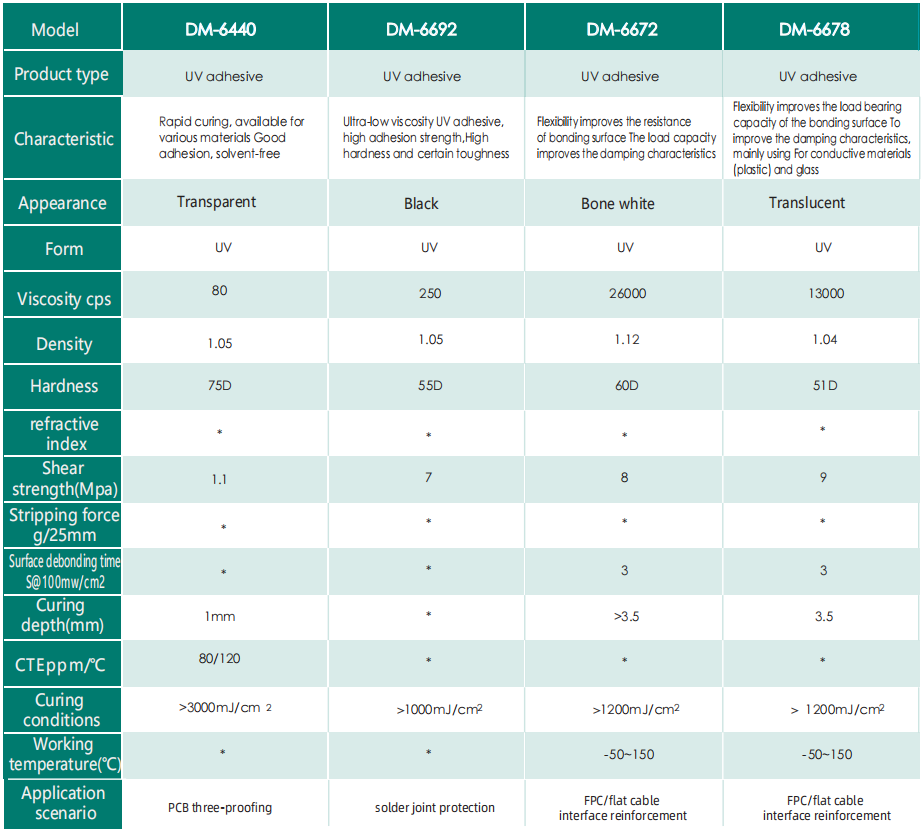

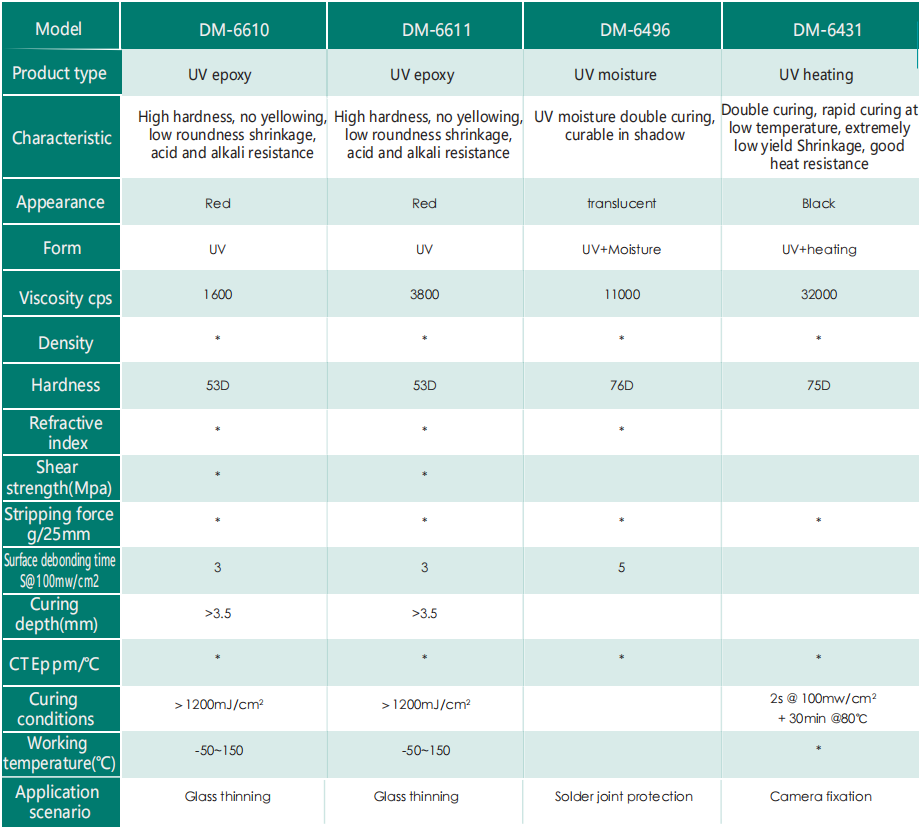

Selection Of One Component UV Adhesive Products

| Product Seriess | Product name | Product typical application |

| Backlight module | DM-6689 | UV nano-imprint adhesive is specially used for the production and manufacture of micro-nano structures, such as lenses, prisms, etc., by master plate imprinting method. The product has high refractive index and rapid curing characteristics, making it particularly suitable for the continuous preparation of micro-nano optical structure films for large size TV and display. |

| DM-6661 | UV nano-imprint adhesive is specially used for the production and manufacture of micro-nano structures, such as lenses, prisms, etc., by the master imprinting method. The product has a refractive index of more than 1.6, which helps to effectively improve the optical efficiency of optical films, and has good anti-falling ball performance. It can be used for the manufacture of small and medium-sized high-refractive prism brightening films. | |

| DM-6662 | UV nano-imprint adhesive is specially used for the production and manufacture of micro-nano structures, such as lenses, prisms, etc., by the master imprinting method. The product has a refractive index of more than 1.6, which helps to effectively improve the optical efficiency of optical films, and has good anti-falling ball performance. It can be used for the manufacture of small and medium-sized high-refractive prism brightening films. | |

| DM-6663 | UV nano-imprint adhesive is specially used for the production and manufacture of micro-nano structures, such as lenses, prisms, etc., by the master imprinting method. The product has a refractive index of more than 1.6, which helps to effectively improve the optical efficiency of optical films, and has good anti-falling ball performance. It can be used for the manufacture of small and medium-sized high-refractive prism brightening films. | |

| DM-6636 | UV-curable acrylate pressure-sensitive adhesive has certain pressure-sensitivity after curing. The formula is based on solvent-free modified acrylate, and the color is colorless or light yellow liquid. The adhesive surface can be cured quickly in a few seconds, thus achieving faster production speed and lower cost. After a period of post-curing after UV curing, the mechanical properties are better. | |

| LCD display | DM-6610 | DM-6610 is a UV-curable epoxy adhesive, which is cured under the ultraviolet radiation with the wavelength of 200-400nm. It has the characteristics of high hardness, no yellowing, low curing shrinkage, and resistance to acid and alkali corrosion. This product is specially designed for the application of glass thinning industry. It is resistant to sulfuric acid and hydrofluoric acid corrosion, and has stable performance in the environment above 50 ℃. It is suitable for the surface coating and sealing bonding of glass, metal and other materials. Typical applications include TFT liquid crystal glass thinning and touch screen glass thinning. |

| DM-6611 | Low shrinkage, acid and alkali corrosion resistance. This product is specially designed for the application of glass thinning industry.It is resistant to sulfuric acid and hydrofluoric acid corrosion, and has stable performance in the environment above 50 ℃. It is suitable for the surface coating and sealing bonding of glass, metal and other materials. Typical applications such as TFT liquid crystal glass thinning, touch screen glass light. | |

| DM-6654 | UV-curable adhesive has high hardness after curing, good adhesion to glass and metal, and excellent chemical resistance, and can be used for sealing of LCD crystal casting. | |

| Peelable blue glue | DM-6606 | A solvent-free, low-viscosity UV-curable environment-friendly sealant. This product is a peelable blue adhesive developed for sealing 3C frame and protecting LCM circuit and electrode. It has the characteristics of non-toxic and non-volatile, short curing time, excellent moisture resistance, and can be repaired. Good film forming property, light peeling force, good elasticity and toughness of cured adhesive layer, and can also be used as UV curing liquid sealing gasket. |

| TWS Headphone assembly | DM-6655 | A UV-curable polyurethane acrylic adhesive with moderate viscosity, high transparency, fast curing speed and good aging resistance. It is applicable to the bonding of various metals and plastics, and can also be used for metal contact protection. |

| DM-6659 | A UV-curable polyurethane acrylic adhesive, used for assembly bonding or device protection, has excellent bonding ability for most substrates, including glass, a variety of plastics and most metals, especially for occasions requiring large gap filling capacity and flexible joint. The flexibility of the product can effectively improve the load bearing capacity of the bonding surface, improve the damping characteristics, and have excellent solvent resistance. | |

| DM-6676 | A medium viscosity, high thixotropic UV-curable adhesive. This product can quickly solidify to form a soft and transparent adhesive layer under the irradiation of sufficient intensity of ultraviolet light. Its flexibility improves the load carrying capacity of the bonding surface and the damping characteristics. It is mainly used for the bonding of voice coil sound films such as speakers and speakers, and also for FPC reinforcement. | |

| DM-6439 | A delayed-curing UV structural adhesive. Its unique molecular structure design enables it to enter the B-stage state under the excitation of UV light, which can be used for rapid UV assembly of opaque substrates. The carefully designed rheological characteristics enable the product to handle the dispensing of ultra-narrow frame, and the gap control can be achieved without the support structure. The product is widely applicable to the bonding of various plastics, glass and metals, and has high reliability under various aging conditions. | |

| Camera module | DM-6605 | UV-curable pressure-sensitive adhesive, specially designed for camera module, is used for dust protection of sensor, and can endure cold and hot cycles for a long time and still remain sticky. |

| DM-6655 | A UV-curable polyurethane acrylic adhesive with moderate viscosity, high transparency, fast curing speed and good aging resistance is suitable for the bonding of various metals and plastics, metal contact protection and camera bracket bonding. | |

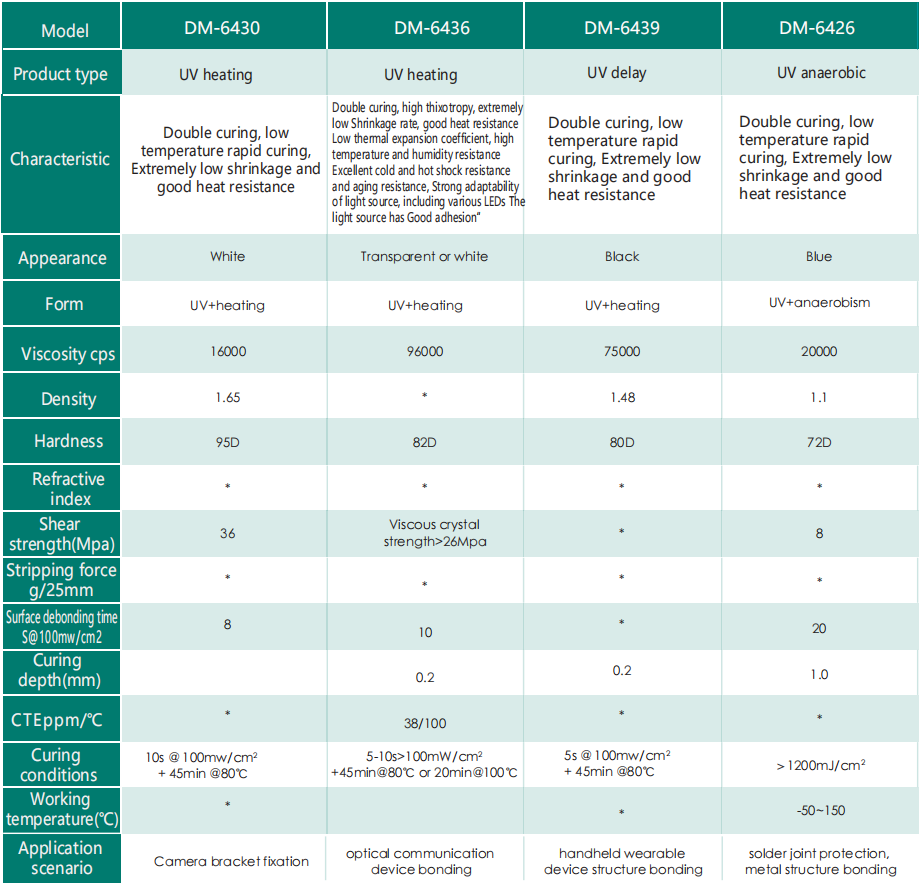

| DM-6430 | UV/thermal double curing adhesive, designed for the bonding and fixation of temperature sensitive devices, can be quickly cured under UV light and positioned, and strengthen the bonding reliability through secondary thermal curing, suitable for the bonding of multi-photo module support. | |

| DM-6439 | UV/thermal double curing adhesive, designed for the bonding and fixation of temperature sensitive devices, can be quickly cured under UV light and positioned, and strengthen the bonding reliability through secondary thermal curing, suitable for the bonding of multi-photo module support. | |

| DM-6650 | A UV-curable adhesive with low viscosity and excellent water vapor barrier performance, suitable for bonding glass and various plastics. | |

| DM-6659 | A UV-curable polyurethane acrylic adhesive, used for assembly bonding or device protection, has excellent bonding ability for most substrates, including glass, a variety of plastics and most metals, especially for occasions requiring large gap filling capacity and flexible joint. The flexibility of the product can effectively improve the load bearing capacity of the bonding surface, improve the damping characteristics, and have excellent solvent resistance. | |

| Solder joint device protection | DM-6653 | UV curing adhesive, specially designed for PIN pin protection, has high hardness, good resistance to moisture and heat aging, and high insulation resistance, which can effectively improve the reliability of solder joint connection. |

| DM-6672 | A UV-curable adhesive with characteristics of rapid curing, good surface drying, high strength, excellent resistance to damp heat and flexibility, and certain gap filling capacity. It can effectively improve the load bearing capacity of the bonding surface and improve the damping characteristics. Applicable to reinforcement, sealing and fixation of FPC and electronic flat cable. | |

| DM-6678 | A UV-curable adhesive with characteristics of rapid curing, good surface drying, high strength, excellent resistance to damp heat and flexibility, and certain gap filling capacity. It can effectively improve the load bearing capacity of the bonding surface and improve the damping characteristics. It is applicable to the reinforcement, sealing and fixation of FPC and electronic flat cable. | |

| Wearable devices | DM-6655 | A UV-curable polyurethane acrylic adhesive with moderate viscosity, high transparency, fast curing speed and good aging resistance is suitable for the bonding of various metals and plastics, metal contact protection and camera bracket bonding. |

| DM-6659 | A UV-curable polyurethane acrylic adhesive, used for assembly bonding or device protection, has excellent bonding ability for most substrates, including glass, a variety of plastics and most metals, especially for occasions requiring large gap filling capacity and flexible joint. The flexibility of the product can effectively improve the load bearing capacity of the bonding surface, improve the damping characteristics, and have excellent solvent resistance. | |

| DM-6676 | A medium viscosity, high thixotropic UV-curable adhesive. This product can quickly solidify to form a soft and transparent adhesive layer under the irradiation of sufficient intensity of ultraviolet light. Its flexibility improves the load carrying capacity of the bonding surface and the damping characteristics. It is mainly used for the bonding of voice coil sound films such as speakers and speakers, and also for FPC reinforcement. | |

| DM-6439 | A delayed-curing UV structural adhesive. Its unique molecular structure design enables it to enter the B-stage state under the excitation of UV light, which can be used for rapid UV assembly of opaque substrates. The carefully designed rheological characteristics enable the product to handle the dispensing of ultra-narrow frame, and the gap control can be achieved without the support structure. The product is widely applicable to the bonding of various plastics, glass and metals, and has high reliability under various aging conditions. | |

| PCB and device protection | DM-6496 | A non-flowing UV/moisture dual-curable packaging adhesive specially designed for PCB packaging protection; It can be cured rapidly under ultraviolet light, and even the shadow that cannot be irradiated by ultraviolet light can be cured at room temperature through moisture. The product has fluorescence under ultraviolet (black) light. |

| DM-6654 | A UV-curable polyurethane acrylic adhesive with moderate viscosity, high transparency, fast curing speed and good aging resistance is suitable for the bonding of various metals and plastics, metal contact protection and camera bracket bonding. | |

| DM-6655 | A UV-curable polyurethane acrylic adhesive with moderate viscosity, high transparency, fast curing speed and good aging resistance is suitable for the bonding of various metals and plastics, metal contact protection and camera bracket bonding. | |

| DM-6440 | A low viscosity UV-curable, and can be used for secondary curing. Therefore, even in shaded areas, the best performance can be ensured. The thin coating can solidify almost instantaneously, and has good adhesion to various metal, ceramic and glass-filled epoxy resin surfaces. This formula is based on solvent-free modified polyurethane acrylate, specially designed to protect printed circuit board. | |

| DM-6692 | A one-component UV-curable circuit protective adhesive. The product has fast curing speed, high adhesive strength, high hardness and certain toughness after curing. The cured product has good resistance to acid, alkali and heat, and is suitable for the protection of small area circuit board area. | |

| DM-6672 | The product is mainly applicable to occasions where large gap filling capacity (0.25mm) and flexible joint are required. It is used to bond hard and flexible PVC to polycarbonate. The flexibility of the product improves the load bearing capacity of the bonding surface and improves the damping characteristics. This product shows excellent bonding ability for most substrates including glass, a variety of plastics and most metals, and is also suitable for BGA bonding. | |

| DM-6678 | A UV-curable adhesive with medium viscosity, rapid curing, good surface drying, high strength, excellent moisture resistance and flexibility. It is applicable to the reinforcement, sealing and fixation of electronic flat cable. | |

| Optical communication device bonding | DM-6436 | A UV heating curing adhesive, suitable for PLC packaging, semiconductor laser packaging, collimator lens bonding, filter bonding, optical detector lens and optical fiber bonding, isolator ROSA bonding. This product can provide reliable positioning and excellent structural bonding performance, with extremely low shrinkage, low coefficient of thermal expansion, hardness, high temperature and humidity resistance, cold and hot shock resistance, and excellent aging resistance. |

Product Data Sheet of One Component UV Adhesive