UV-curable adhesive systems are rapidly gaining popularity in various industries due to their numerous benefits over traditional adhesive systems. These adhesives cure quickly, have high bond strength, low toxicity, and provide improved aesthetics, among other benefits. This article will provide a comprehensive guide to UV curable adhesive systems, including their types, applications, choosing the right system, applying and curing, and the benefits they offer.

What are UV Curable Adhesive Systems?

UV-curable adhesive systems are a type of adhesive that cures when exposed to UV light. When exposed to UV light, they work by undergoing polymerization or cross-linking. Curing occurs rapidly, typically in seconds, resulting in a strong bond.

Compared to traditional adhesive systems, UV-curable adhesive systems offer several advantages. These include:

- Fast curing times

- High bond strength

- Low toxicity

- Improved aesthetics

- Reduced waste

Several UV-curable adhesive systems, including acrylate urethanes, epoxies, and silicones, are available. Each class has a different chemical composition that affects its curing properties.

Applications of UV Curable Adhesive Systems

UV-curable adhesive systems are commonly used in various industries, including:

- Medical device manufacturing

- Electronics assembly

- Automotive manufacturing

- Packaging

- Printing and graphics

- Woodworking

- Construction

These adhesives can improve manufacturing efficiency and product quality by providing the following:

- Faster production times

- Consistent quality

- Stronger bonds

- Reduced waste

Some unique applications of UV-curable adhesive systems include manufacturing medical devices and electronics, where they provide a strong bond without heat, which could damage sensitive components.

Types of UV Curable Adhesive Systems

Various UV-curable adhesive systems are available, each with unique features and benefits. Understanding the differences between these systems is essential when selecting the most suitable adhesive for your specific application. Here are some common types of UV-curable adhesive systems:

- One-Component UV-Curable Adhesives:These adhesives are pre-mixed and ready to use. They cure when exposed to UV light and do not require mixing before use. One-component sealants are ideal for bonding small components but may not be suitable for large assemblies or high-stress applications.

- Two-Component UV Curable Adhesives:These adhesives consist of two parts: a resin and a hardener. The resin and hardener are mixed together before application, and the adhesive cures when exposed to UV light. Two-component adhesives offer greater flexibility and bond strength than one-component adhesives.

- Flexible UV-Curable Adhesives:These adhesives are designed to bond substrates that require some degree of flexibility, such as plastics, rubbers, and elastomers. Flexible UV-curable adhesives can withstand vibration, shock, and thermal cycling.

- Rigid UV-Curable Adhesives:These adhesives are ideal for bonding rigid substrates, such as glass, metal, and ceramics. Harsh UV curable adhesives provide high bond strength and resist chemicals and solvents.

- High-Temperature UV-Curable Adhesives:These adhesives are designed to withstand high temperatures and provide excellent bonding strength in extreme environments. High-temperature UV curable adhesives are ideal for bonding substrates that require resistance to heat, such as metals, ceramics, and glass.

Choosing the Right UV Curable Adhesive System

When choosing a UV-curable adhesive system, several factors should be considered, including:

- Substrate materials

- Curing time

- Required bond strength

- Flexibility requirements

Choosing the right adhesive system for the specific application ensures a solid and durable bond. Proper surface preparation is also critical for achieving optimal bond strength.

Applying and Curing UV Curable Adhesive Systems

Proper application and curing of UV-curable adhesive systems are essential to achieving optimal bond strength. Here are the steps for applying and curing UV-curable adhesive systems:

Step 1: Surface preparation – Proper surface preparation is essential to achieving optimal bond strength. The surface should be free of any dirt, grease, or other contaminants. It is recommended to clean the surface with an appropriate solvent and then dry it thoroughly.

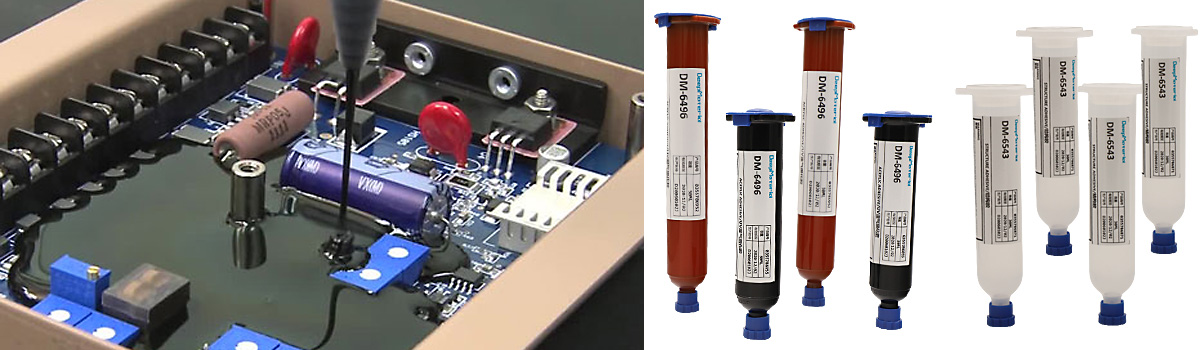

Step 2: Dispensing – The adhesive should be dispensed accurately onto the substrate. The type of dispensing equipment used will depend on the adhesive system and application.

Step 3: Assembly – The substrate should be assembled immediately after dispensing the adhesive to ensure proper bonding. The parts should be aligned correctly and clamped or fixed to prevent movement during the curing process.

Step 4: Curing – The process should be carried out according to the adhesive system’s specifications. The curing process can be achieved through various methods, such as UV lamps, LED lamps, or laser curing.

Tips for troubleshooting common issues that may arise during the curing process:

- Insufficient cure:If the adhesive is not fully cured, increase the curing time or intensity of the curing source.

- Yellowing: If the adhesive is yellowing after curing, try reducing the curing time or intensity of the curing source.

- Poor adhesion:If the adhesive is not bonding well, consider surface preparation or changing the adhesive system.

Benefits of UV Curable Adhesive Systems

UV-curable adhesive systems offer numerous benefits over traditional adhesive systems. Here are some of the key benefits:

- Fast curing times– UV repairable adhesive systems cure rapidly, significantly reducing production time.

- High bond strength– UV curable adhesive systems offer excellent strength, resulting in reliable, long-lasting bonds.

- Low toxicity– UV curable adhesive systems are generally low in toxicity, making them a safer option for workers and the environment.

- Improved aesthetics– UV curable adhesive systems offer improved aesthetics by eliminating the need for visible fasteners, enhancing the appearance of the finished product.

- Reduced waste– UV curable adhesive systems require minimal cleanup, reducing waste and improving efficiency.

- Improved product performance– UV-curable adhesive systems can improve product performance by reducing vibration, noise, and stress.

Investing in UV-curable adhesive systems is wise for businesses looking to improve their manufacturing processes and product quality.