The adhesive industry has experienced a revolution with the introduction of flexible UV-curing adhesives, which have unique properties that make them ideal for various industries. Professionals design these adhesives for bonding a wide range of substrates, providing the flexibility and durability required in many applications. They are also known for their fast curing times and resistance to temperature and humidity changes.

In this blog post, we’ll dive into the world of flexible UV-curing adhesives and explore their benefits, applications, and how to select the suitable adhesive for your industry.

What are flexible UV-curing adhesives?

Professionals use two-part adhesives that consist of a resin and a hardener to create flexible UV-curing adhesives that cure when exposed to UV light. They commonly use these adhesives in applications requiring high adhesion strength and flexibility. They offer excellent bonding properties that allow them to bond with a wide range of substrates, including metals, plastics, and composites.

The curing process of these adhesives is fast and precise, allowing for efficient manufacturing processes. They are also known for their ability to provide a strong and durable bond, even under harsh environmental conditions.

Benefits of flexible UV-curing adhesives

Flexible UV-curing adhesives offer several benefits that make them ideal for various industries. Let’s explore some of these benefits in detail.

Ability to bond dissimilar materials

Flexible UV-curing adhesives have a significant advantage in bonding dissimilar materials. Professionals often consider this feature ideal for connecting multiple substrates in various applications. They can click materials such as metal to plastic, plastic to rubber, and even glass to metal.

This feature reduces the need for additional adhesives and makes manufacturing more efficient.

Flexibility and durability

Professionals prefer flexible UV-curing adhesives for their ability to provide the flexibility and durability needed in many applications. They specifically design these adhesives to withstand stress and movement, making them an ideal choice for applications that involve vibration or movement.

They are also known for their resistance to impact, making them ideal for high-shock load applications. The flexibility and durability of these adhesives make them suitable for industries such as automotive, electronics, and aerospace.

Fast curing times and improved efficiency

Flexible UV-curing adhesives also offer fast curing times, improving production process efficiency. Since they cure upon exposure to UV light, they can be used in automated processes, reducing the need for manual labor and increasing throughput. The curing time can be a few seconds, depending on the adhesive and the intensity of the UV light source.

Fast curing times of UV-curing adhesives can reduce the likelihood of adhesive failure due to movement or misalignment of parts during the bonding process. This feature is essential in electronics and medical devices, where precision and reliability are critical, and fast curing times can improve efficiency.

Resistance to temperature and humidity changes

Flexible UV-curing adhesives can withstand temperature and humidity changes, making them ideal for applications with varying environmental conditions. They can maintain their bond strength and flexibility over a wide temperature range, from -40°C to 150°C, making them suitable for harsh environments.

The automotive, aerospace, and electronics industries require adhesives that can withstand extreme temperatures and humidity, making resistance to these factors essential. By using flexible UV-curing adhesives, manufacturers can ensure that their products maintain performance and reliability over the long term.

Applications of flexible UV-curing adhesives

Flexible UV-curing adhesives have a wide range of applications across various industries. Here are some examples:

Automotive industry

Flexible UV-curing adhesives are commonly used in the automotive industry to bond dissimilar materials, such as plastic and metal, and create seals and gaskets. They can withstand the harsh conditions of engine compartments and provide reliable bonding for critical components.

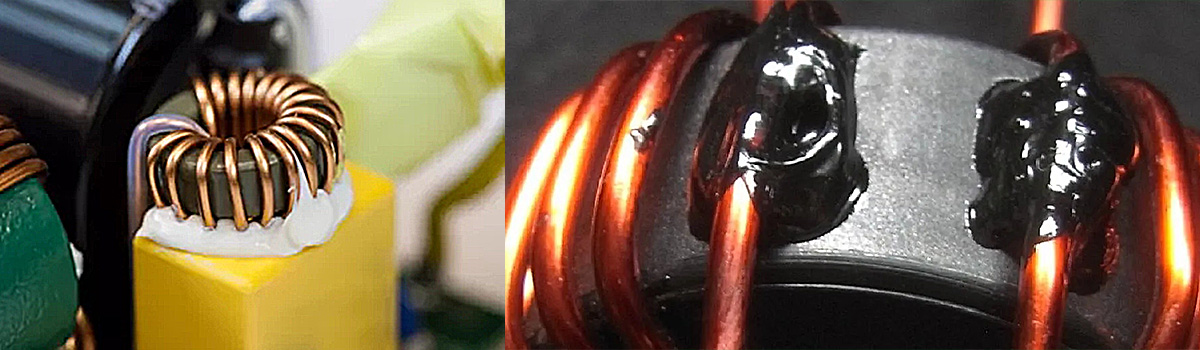

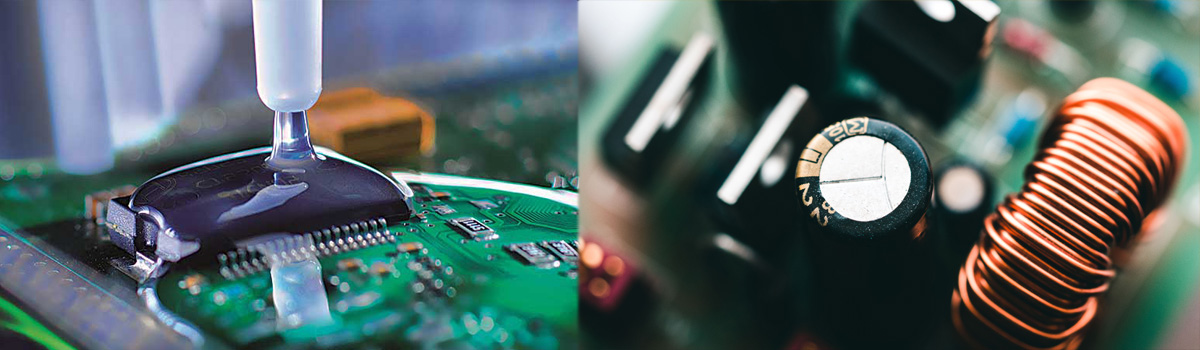

Electronics industry

The electronics industry uses flexible UV-curing adhesives to bond components like printed circuit boards and displays screens and create seals and gaskets. They offer fast curing times and excellent adhesion strength, which is critical for the reliability and performance of electronic devices.

Medical device industry

The medical device industry uses flexible UV-curing adhesives to bond components and creates seals and gaskets for medical equipment. They offer excellent biocompatibility and can withstand sterilization, making them suitable for various medical applications.

Aerospace industry

Flexible UV-curing adhesives bond components and create seals and gaskets for aircraft and spacecraft in the aerospace industry. They offer excellent resistance to temperature and humidity changes, which is critical for the performance and reliability of aerospace components.

How to select the right flexible UV-curing adhesive

Selecting the suitable flexible UV-curing adhesive for your application requires careful consideration of several factors. Here are some key considerations:

Considerations for material compatibility

When selecting a flexible UV-curing adhesive, it’s essential to consider the compatibility of the bond with the materials that require bonding. Some adhesives may not be suitable for certain materials, such as metals or plastics, and may require a different glue or surface treatment.

Considerations for the curing process and equipment

The process and equipment used for curing flexible UV-curing adhesives vary depending on the application. For example, if you use an automated process, you may need a fast-curing adhesive and a high-intensity UV light source to cure the adhesive.

Considerations for environmental conditions

When engineers and designers select a flexible UV-curing adhesive, they should consider the specific environmental conditions to which they will expose the bond in its intended application. Flexible UV-curing adhesive includes temperature, humidity, and exposure to chemicals or other potentially damaging substances.

Different adhesives have varying levels of resistance to environmental conditions, so choosing a bond that can withstand the specific needs it will encounter is essential. For example, adhesives used in outdoor applications or the automotive industry must withstand extreme temperatures and weather conditions. In contrast, adhesives used in the electronics industry must be able to handle high levels of heat and humidity.

In addition to environmental conditions, it’s also essential to consider the potential for exposure to chemicals or other substances that could degrade the adhesive over time. For example, adhesives used in the medical device industry must withstand exposure to various sterilization methods. In contrast, adhesives used in the aerospace industry must withstand exposure to jet fuel and other aviation-related chemicals.

When selecting a flexible UV-curing adhesive, you should consider the specific environmental conditions it will encounter and choose a bond that can handle those conditions. Manufacturers should also consider testing the glue in the specific ecological conditions it will be exposed to ensure that it meets the required performance standards.

Exploring Flexible UV-Curing Adhesives

In addition to flexible UV-curing adhesives, several associated keywords are relevant to this topic. These keywords include:

- UV adhesive:An adhesive can cure when exposed to ultraviolet light, making it a UV adhesive.

- Flexible bonding: Flexible bonding refers to the ability to create strong bonds between materials with different properties, such as flexibility, without compromising the integrity of the bond.

- Curing time: The length of the adhesive to fully cure and reach its maximum strength.

- Adhesion strength: The force required to break the bond between two materials.

- Material compatibility:The ability of the adhesive to bond with specific materials without causing damage or degradation.

- Temperature resistance:The ability of an adhesive to maintain its bonding strength despite temperature changes is known as temperature resistance.

Flexible UV-curing adhesives offer numerous benefits for various industries, including their ability to bond dissimilar materials, withstand temperature and humidity changes, and improve efficiency through fast curing times. By selecting a suitable adhesive for the application and considering factors such as material compatibility and environmental conditions, manufacturers can ensure a solid and durable bond for their products.

As more industries continue to explore the possibilities of using flexible UV-curing adhesives, it’s essential to consider the benefits and considerations outlined in this blog post. By doing so, manufacturers can improve their products’ quality and performance while reducing costs and production time.