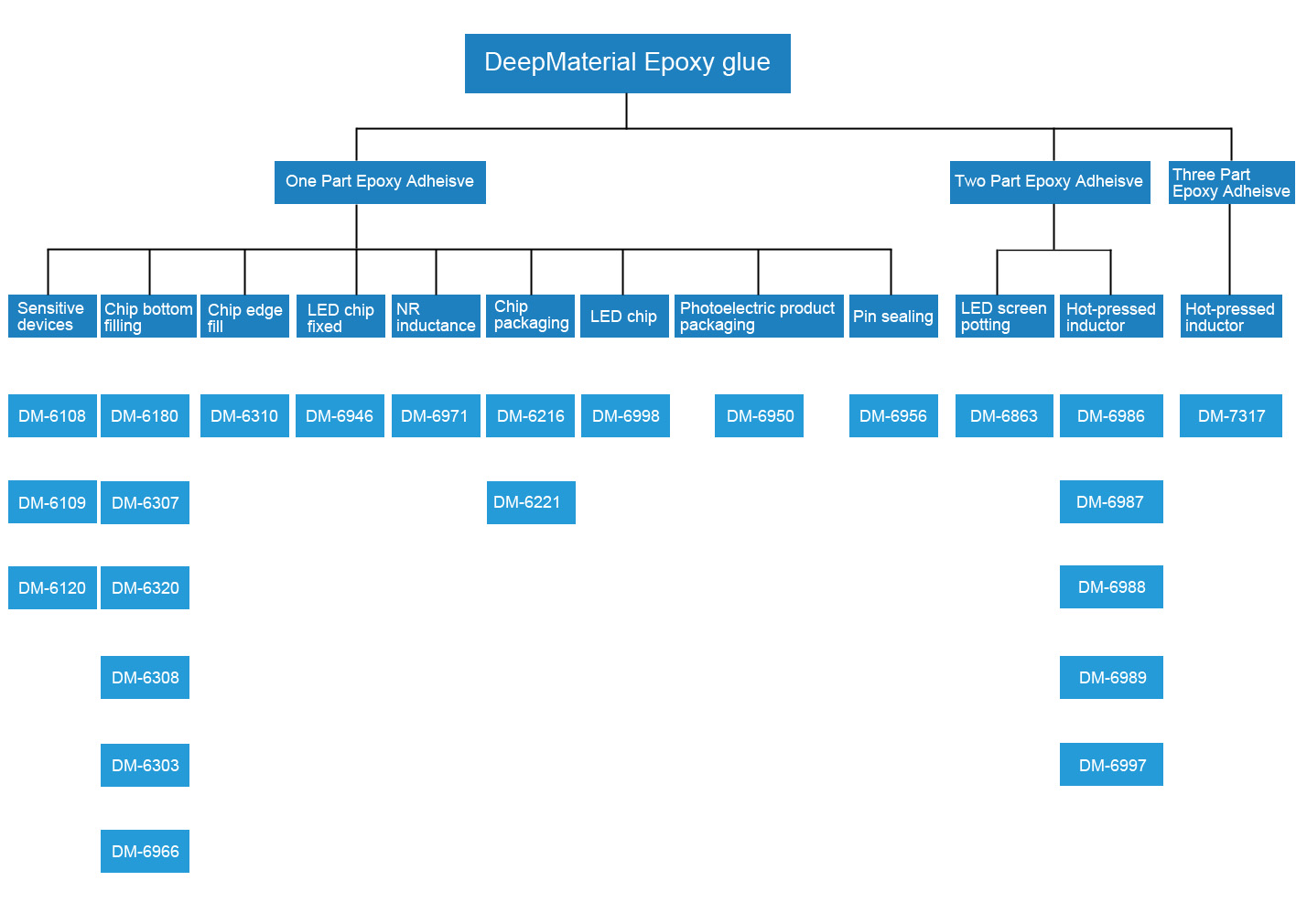

Epoxy adhesives

Deepmaterial manufacturing custom epoxy adhesives

Industrial epoxy adhesives

DeepMateriacl is the best industrial epoxy adhesives

Deepmaterial is a China industrial adhesive manufacturer specializing in (supplying) epoxy adhesives. With deep market and application knowledge, Deepmaterial’s experts are curious and passionate. We offer an unmatched portfolio of one component UV adhesives, sealants, and functional coatings that will help you transform markets and your business. We are your global partner, ready to tackle any challenge, and together, we will find a smart and sustainable solution.

Epoxy adhesives

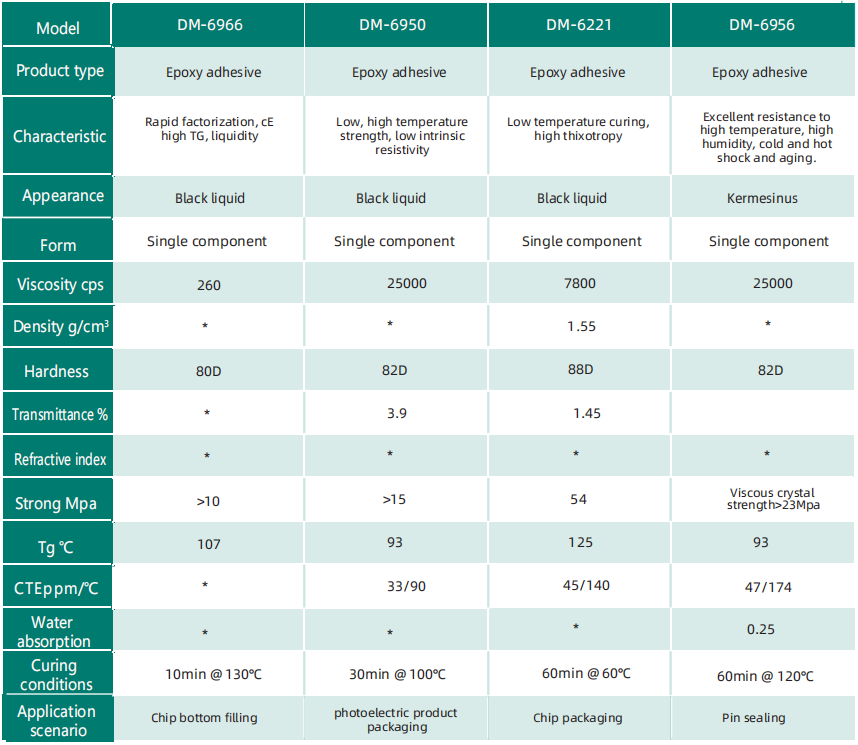

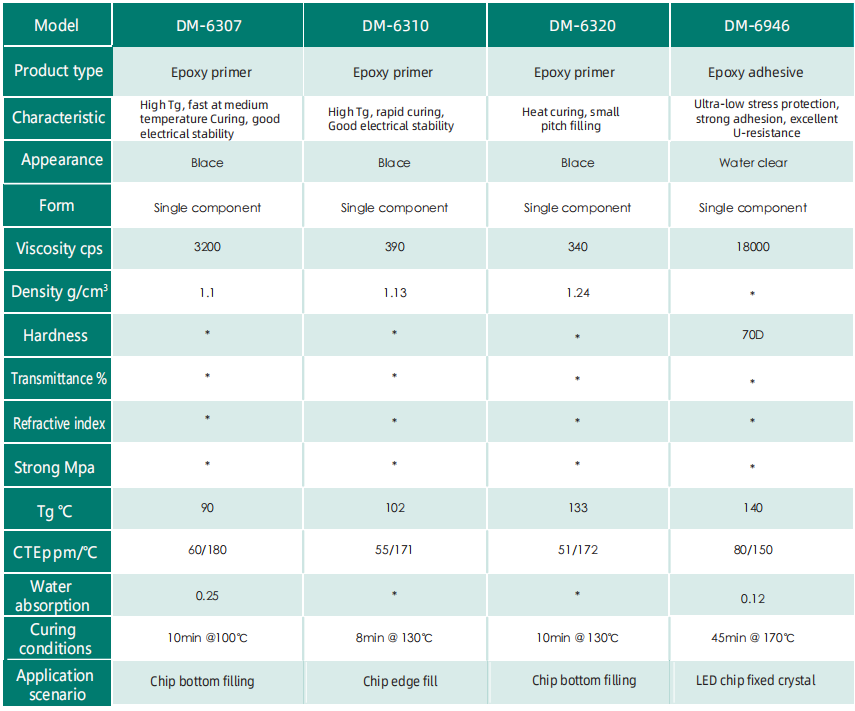

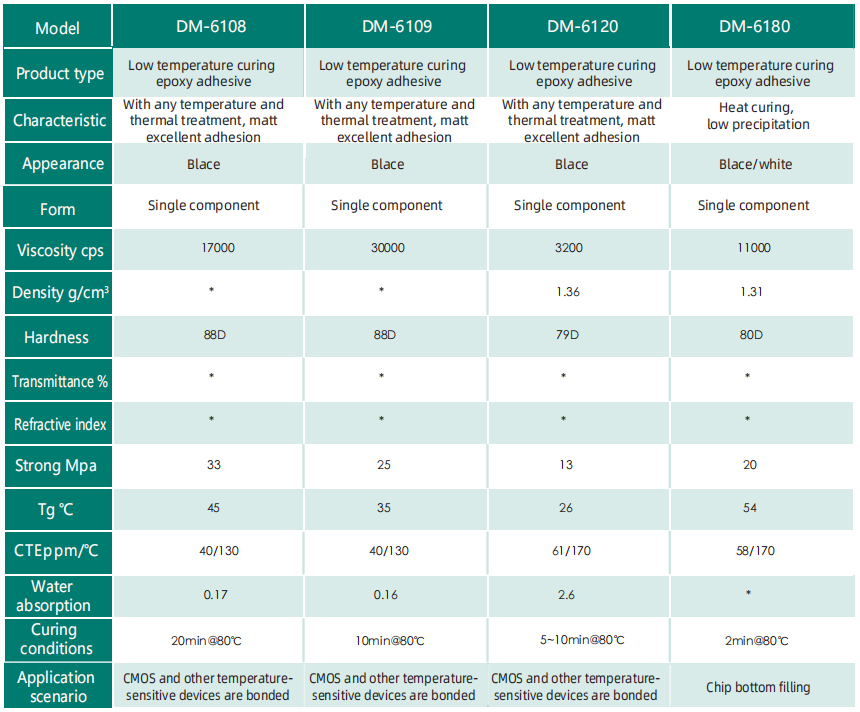

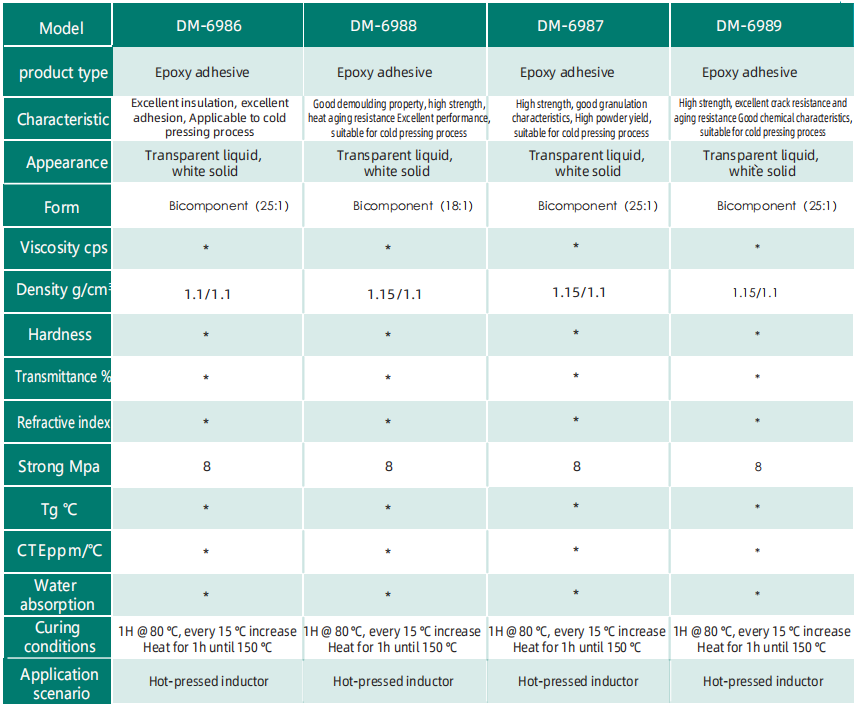

Epoxy Adhesive Product Selection

| Product Seriess | Product name | Product typical application |

| Chip Bottom Filling | DM-6180 | Low-temperature curing epoxy adhesive series products are designed for the bonding and fifixation of temperature sensitive devices. They can be cured at as low as 80 ℃ and have good adhesion to a variety of materials in a relatively short time.Typical applications: bonding of IR fifilter and base, and bonding of base and substrate. |

| DM-6307 | An epoxy primer, which can realize rapid curing at a relatively low temperature and minimize the stress on other parts. After curing, it can provide excellent mechanical properties and protect solder joints under thermal cycling conditions. Suitable for BGA/CSP packaging chip bottom fifilling protection. | |

| DM-6320 | The bottom fifiller is specially designed for BGA/CSP packaging process. It can rapidly solidify at appropriate temperature to reduce the thermal stress of the chip and improve the reliability of the solder joint under cold and hot cycling conditions. | |

| DM-6308 | A one-component epoxy primer for the manufacture of LED splicing screen in COB packaging process. The product has low viscosity, good adhesion and high bending strength, which can quickly and effffectively fifill the tiny gap between chips and effffectively enhance the reliability of chip mounting. | |

| DM-6303 | A one-component epoxy primer for the manufacture of LED splicing screen in COB packaging process. The product has low viscosity, good adhesion and high bending strength, which can quickly and effffectively fifill the tiny gap between chips and effffectively enhance the reliability of chip mounting. | |

| Sensitive Devices | DM-6109 | Low-temperature curing epoxy adhesive series products are designed for the bonding and fifixation of temperature sensitive devices. They can be cured at as low as 80 ℃ and have good adhesion to a variety of materials in a relatively short time.Typical applications: bonding of IR fifilter and base, and bonding of base and substrate. |

| DM-6120 | Low-temperature curing epoxy adhesive series products are designed for the bonding and fifixation of temperature sensitive devices. They can be cured at as low as 80 ℃ and have good adhesion to a variety of materials in a relatively short time.Typical applications: bonding of IR fifilter and base, and bonding of base and substrate. | |

| Chip Edge Fill | DM-6310 | An epoxy primer, which can realize rapid curing at a relatively low temperature and minimize the stress on other parts. After curing, it can provide excellent mechanical properties and protect solder joints under thermal cycling conditions. Suitable for BGA/CSP packaging chip bottom fifilling protection. |

| LED Chip Fixed | DM-6946 | Composite epoxy resin is a product developed to meet the high-end packaging technology of LED in the market. It is suitable for various LED packaging and solidifification. After curing, it has low internal stress, strong adhesion, high temperature resistance, low yellowing, and good weather resistance. |

| NR Inductance | DM-6971 | A one-component epoxy adhesive specially designed for NR inductance coil encapsulation. The product has smooth dispensing, fast curing speed, good molding effffect, and is compatible with all kinds of magnetic particles. |

| Chip Packaging | DM-6221 | A one-component epoxy resin adhesive with low curing shrinkage, high adhesive strength and good adhesion tomany materials. It is suitable for fifilling and sealing of various precision electronic components, mainly used for fifilling and sealing of automotive sensors and on-board electronic contactors. |

| Photoelectric Product Packaging | DM-6950 | A one-component epoxy adhesive specially designed to encapsulate the bonding structure of photoelectric products. This product is suitable for low-temperature curing and has good adhesion to a variety of materials in a short time, especially plastic products. |

| Hot-pressed inductor | DM-6986 | A two-component epoxy adhesive, specially designed for the integrated induction cold pressing process, has high strength,excellent electrical performance and strong versatility. |

| DM-6987 | A two-component epoxy adhesive specially designed for the integrated induction cold pressing process. The product has聽high strength, good granulation characteristics and high powder yield. | |

| DM-6988 | A two-component high-solid epoxy adhesive, specially designed for the integrated induction cold pressing process, has high strength, excellent electrical performance and strong versatility. | |

| DM-6989 | A two-component epoxy adhesive specially designed for the integrated induction cold pressing process. The product has high strength, excellent cracking resistance and good aging resistance. | |

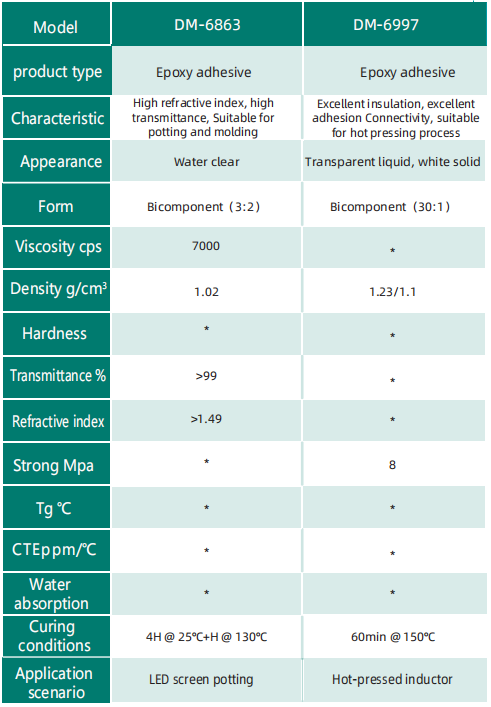

| DM-6997 | A two-component epoxy adhesive specially designed for the integrated induction hot-pressing process. The product has good demoulding performance and strong versatility. | |

| LED screen potting | DM-6863 | A two-component transparent epoxy adhesive used for the manufacture of LED splicing screen in GOB packaging process.The product has fast gel speed, low curing shrinkage, less aging yellowing,high hardness and friction resistance. |

Product Data Sheet of Epoxy Adhesive