Optical products’ manufacturing and assembly process requires precision and high-quality materials to ensure that the final product is durable and reliable. UV-curing optical adhesive has become an essential component in manufacturing, offering several benefits over traditional adhesives. UV curing optical adhesive offers faster curing times, stronger bonds, and improved optical properties. In this blog post, we will explore the properties and benefits of UV-curing optical adhesives and their various applications in the optical industry.

What is UV curing optical adhesive?

UV curing optical adhesive is an adhesive that cures when exposed to ultraviolet light. It is a two-part adhesive that consists of a liquid adhesive and a photoinitiator. When exposed to UV light, the photoinitiator triggers a chemical reaction that causes the adhesive to harden and form a strong bond. UV curing adhesive is available in different formulations to suit various applications.

Definition and properties of UV curing optical adhesive:

UV curing optical adhesive is a type of adhesive that offers several benefits over traditional adhesives. It is a two-part adhesive designed to cure quickly when exposed to ultraviolet light, and UV curing adhesive offers improved strength and durability, better optical properties, and resistance to temperature and humidity.

How does UV curing work?

UV curing adhesive contains a photoinitiator that is activated when exposed to ultraviolet light. The photoinitiator triggers a chemical reaction that causes the adhesive to harden and form a strong bond. The curing time of UV curing adhesive is much faster than traditional adhesives, making it ideal for applications that require fast curing times.

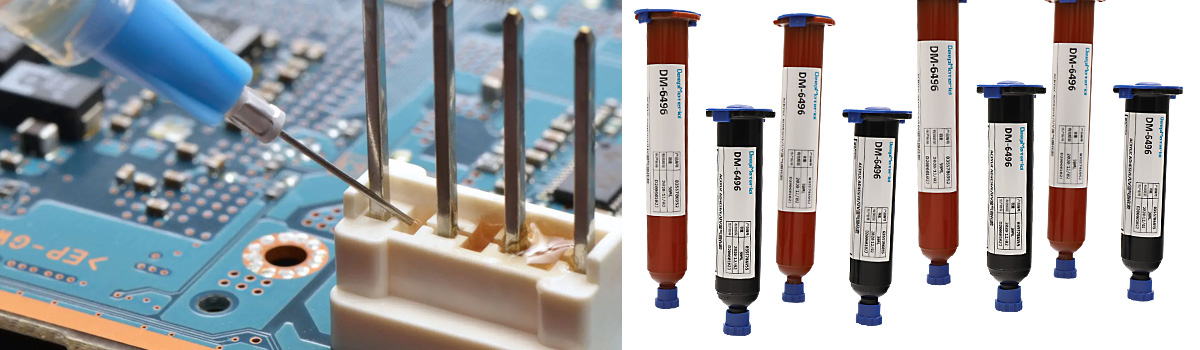

Types of UV curing optical adhesive:

UV curing adhesive is available in different formulations to suit various applications. Some of the common types of UV curing adhesive include:

- Acrylic-based UV curing adhesive is ideal for bonding plastics, glass, and metals. It offers excellent bonding strength and resistance to temperature and humidity.

- Epoxy-based UV curing adhesive is ideal for bonding metals, ceramics, and glass. It offers high bonding strength and excellent chemical resistance.

- Silicone-based UV curing adhesiveis ideal for bonding flexible materials such as rubber, plastics, and fabrics. It offers excellent flexibility and resistance to temperature and humidity.

Advantages of UV curing optical adhesive:

UV-curing optical adhesive offers several advantages over traditional adhesives. Some of the benefits include the following:

Faster curing times:

UV-curing adhesive cures much faster than traditional adhesives. This is because the adhesive cures when exposed to UV light, which triggers a chemical reaction that causes the adhesive to harden and form a strong bond.

More robust bonds and improved durability:

UV curing adhesive offers improved bonding strength and durability compared to traditional adhesives. This is because the adhesive forms a stronger bond when exposed to UV light, resulting in a more robust and durable bond.

Improved optical properties:

UV curing adhesive offers improved optical properties compared to traditional adhesives. This is because the adhesive is transparent and does not yellow over time, resulting in better visual clarity and performance.

Resistance to temperature and humidity:

UV curing adhesive offers excellent resistance to temperature and humidity, making it ideal for applications that require a durable and reliable bond in harsh environments.

Applications of UV Curing Optical Adhesive

UV-curing optical adhesive has become an indispensable material in the optical industry due to its excellent properties and characteristics. Here are some of the most common applications of UV-curing optical adhesive:

Lens Bonding

UV curing optical adhesive is extensively used in lens bonding for various optical instruments, such as cameras, binoculars, and telescopes. Optical lenses require special bonding to prevent air bubbles or impurities that may distort the optical path. UV curing optical adhesive provides a robust and evident bond and has excellent optical transmission properties. The adhesive also resists yellowing and does not affect the refractive index of the lens material.

Fiber Optic Assembly

Fiber optic cables are essential components in the telecommunications and data communication industries. UV curing optical adhesive attaches the fiber to the connector and secures it in place. The adhesive creates a strong bond between the fiber and the connector, ensuring reliable and consistent optical performance.

LCD and OLED Display Assembly

UV curing optical adhesive is widely used to assemble LCD and OLED displays. The adhesive bonds the display’s layers and attaches the shoe to the frame or housing. UV curing optical adhesive provides a robust and evident bond that ensures optimal visual performance and minimizes the risk of any air bubbles or impurities.

Optical Filter Bonding

Optical filters are used in various optical instruments to adjust the spectral characteristics of light. UV curing visual adhesive bonds the filter to the lens or other components. The adhesive provides a robust and evident bond that ensures optimal optical transmission and minimizes any distortion or degradation of the filter.

Optoelectronic Packaging

UV-curing optical adhesive is also used in packaging optoelectronic devices, such as LEDs, photodiodes, and laser diodes. The adhesive attaches the device to the substrate or housing and protects it from external factors, such as moisture and temperature. UV curing optical adhesive provides a robust and evident bond that ensures reliable and consistent visual performance.

Best Practices for Using UV Curing Optical Adhesive

To ensure optimal performance and reliability of optical products, it is essential to follow proper procedures for using UV-curing optical adhesive. Here are some best practices for using UV-curing optical adhesive:

Proper Surface Preparation

Proper surface preparation ensures a strong bond between the adhesive and the substrate. The surface should be cleaned thoroughly and free from contaminants like dust, grease, or oils. The surface should also be roughened or etched to increase the surface area and enhance the bond strength.

Selection of Appropriate Adhesive

Selecting the appropriate adhesive is essential to ensure optimal performance and reliability of the optical product. The adhesive should be compatible with the substrate and provide the required optical properties, such as transparency, refractive index, and UV transmission. The adhesive should also have appropriate viscosity, wettability, and rheology to ensure easy application and proper coverage.

Optimal Curing Conditions

Optimal curing conditions are critical to ensure complete adhesive curing and optimal bond strength. The curing conditions depend on the adhesive type, thickness, and substrate material. UV curing requires exposure to UV light of the appropriate wavelength and intensity for the time necessary. The curing conditions should be optimized to ensure complete curing without residual stress or shrinkage.

Quality Control and Testing

Quality control and testing are essential to ensure the reliability and consistency of the optical product. The adhesive bond strength, optical transmission, and durability should be tested using appropriate methods and equipment. Quality control procedures should be established and followed to ensure consistent product quality and to identify and correct any issues.